Case Study:

Delivers First MLT TAML Level 5 in Balder Field

Key Challenges

- Narrow Operating Window

- Losses in reservoir section

- Unstable shales

Benefits

- Reduced operational time

- Drilling fluid cost savings

- Increased reservoir lengths recovery

EC-Drill® delivers first MLT well in Balder field, optimizing production, reducing costs, and enabling successful drilling in challenging reservoirs

Challenge:

Accelerate production and drain remaining oil reserves from the depleted Balder reservoir. Balder field resources consist of drilling through faults and fracture discontinuities as well as injectites with associated fractures. This complex drilling environment had been a huge challenge resulting in significant operational delays because of losses and wellbore instabilities. The consequences was lost time and increased costs due to managing hole problems, re-drilling sections, and shorter reservoir sections with less production.

Additional reading: Discover how EC-Drill® and RMR® provided large savings for Shell in this success story.

Solution:

The engineering team decided to drill the first multilateral (MLT) TAML level 5 well in the already depleted Balder reservoir. They chose EC-Drill® technology, which uses the Controlled Mud Level MPD method, to stay within the expected operating window and to address any drilling challenges.

Results:

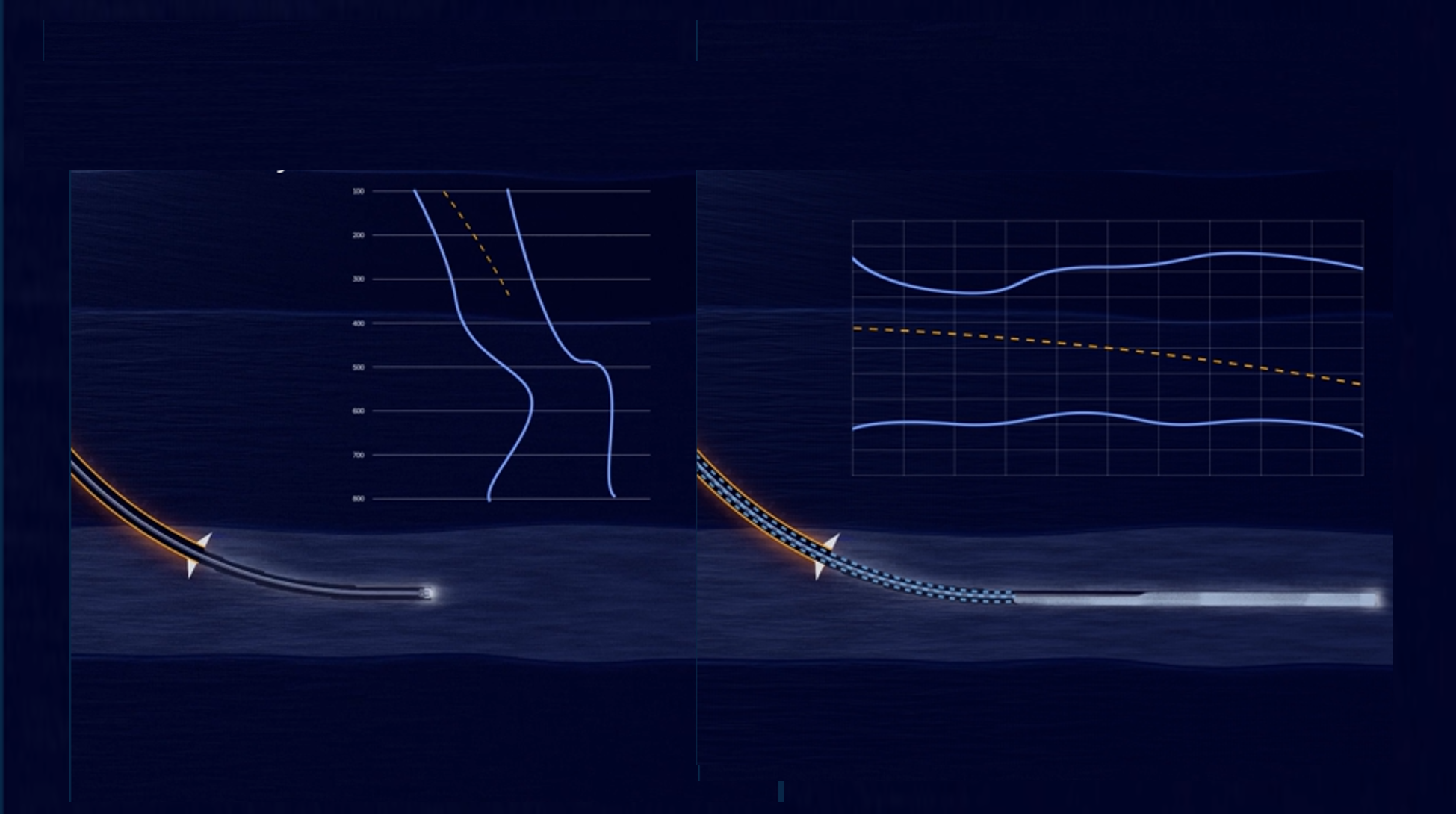

Maintain ECD/ESD within limits (SH-min and Shear-Failure) by manipulating riser level during drilling and connections through lateral section.

The mainbore and lateral was drilled using EC-Drill® to operate within the narrow margins. The plot above show the actual Bottom Hole Pressures (Blue Curve) observed in the lateral section and the adjustments made to the Riser Level (Orange area). EC-Drill® kept the pressures within an operating window of 0.05SG. The unique Dual Gradient Effect caused by the Controlled Mud Level method ensured the resulting pressure at the Shoe did not exceed the upper boundary while maintaining a near Constant Bottom Hole pressure at TD. During the campaign, no losses or wellbore instability issues were encountered while drilling.

The first MLT well at Balder field was completed significantly ahead of AFE. It was the longest reservoir section ever drilled and completed in the Balder Area - 257m longer than the previously longest section.

Learn more about the EC-Drill® in this webinar, where representatives from Lundin and Equinor showcase how this technology has beed used successfully in different scenarios and to solve typical drilling challenges.

Challenge solved:

EC-Drill® assisted in enabling the well to be successfully drilled in a challenging environment and helped unlock a larger area of the reservoir. It also optimized operations playing a crucial role in completing the well, faster than planned. EC-Drill® is now used consistently in the Balder field and have participated in the successful completion of another seven wells, pushing the boundaries of what is achievable even further.

Conclusion:

- EC-Drill® enabled drilling in depleted reservoir

- EC-Drill® enabled longer reservoir section to be drilled unlocking more reserves

- EC-Drill® helped optimize operations completing the well ahead of AFE

- EC-Drill® used for Drilling and Completion

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

RMR® Technology

INPEX, Browse Basin

Read Case Study:

EC-Drill® Technology

Dual Gradient in Gulf of Mexico Deepwater

Read Case Study: