Case Study:

EC-Drill® Assists Operator Increase Tripping Speed and Save Rig Time

Key Challenges

- Depleted sand reservoir

- Lowered fracture gradient

- Fault zones prone to losses

- Loss circulation

Benefits

- Reduces Surge Pressure and faster tripping speeds

- Reduces risk of lost circulation

- Enables accurate volume control during tripping

- Saves rig time during tripping operations

By applying the EC-Drill® Controlled Mud Level system on the Troll field, tripping speed was increased by 50 per cent.

Challenge

Limited running speeds due to surge pressure through weak sands with long horizontal Open Hole screens. Running screens on the Troll field has traditionally required limited tripping speeds to avoid surge pressure exceeding the fracture gradient of the depleted sand reservoir.

The Troll field has long horizontal MLT wells through a thin sand reservoir with low pressure. The sand reservoir has become depleted over many years of production and contains fault zones, resulting in lost circulation challenges. The MLT design normally has 3 branches of 8 ½” open hole that reach horizontal lengths of 4500 to 6000m with stand-alone screens. The water based mud weight is between 1.05 and 1.07 sg and cannot be lowered any further. Conventionally the tripping speed of the long screen sections had to be limited to avoid losses. Fig 1 shows the calculated tripping speed for running on a full riser for a particular well. The tripping speed would need to be limited and adjusted throughout running the screens to avoid the surge pressure exceeding the fracture gradient.

The Equinox rig on the Troll field is one of the most technological advanced for connections and tripping. The technology has enabled the rig of being among the most efficient on the Norwegian Continental Shelf. Being required to limit the tripping speeds for screens during multiple long laterals for each well will add substantial time and reduces the efficiency of the rig.

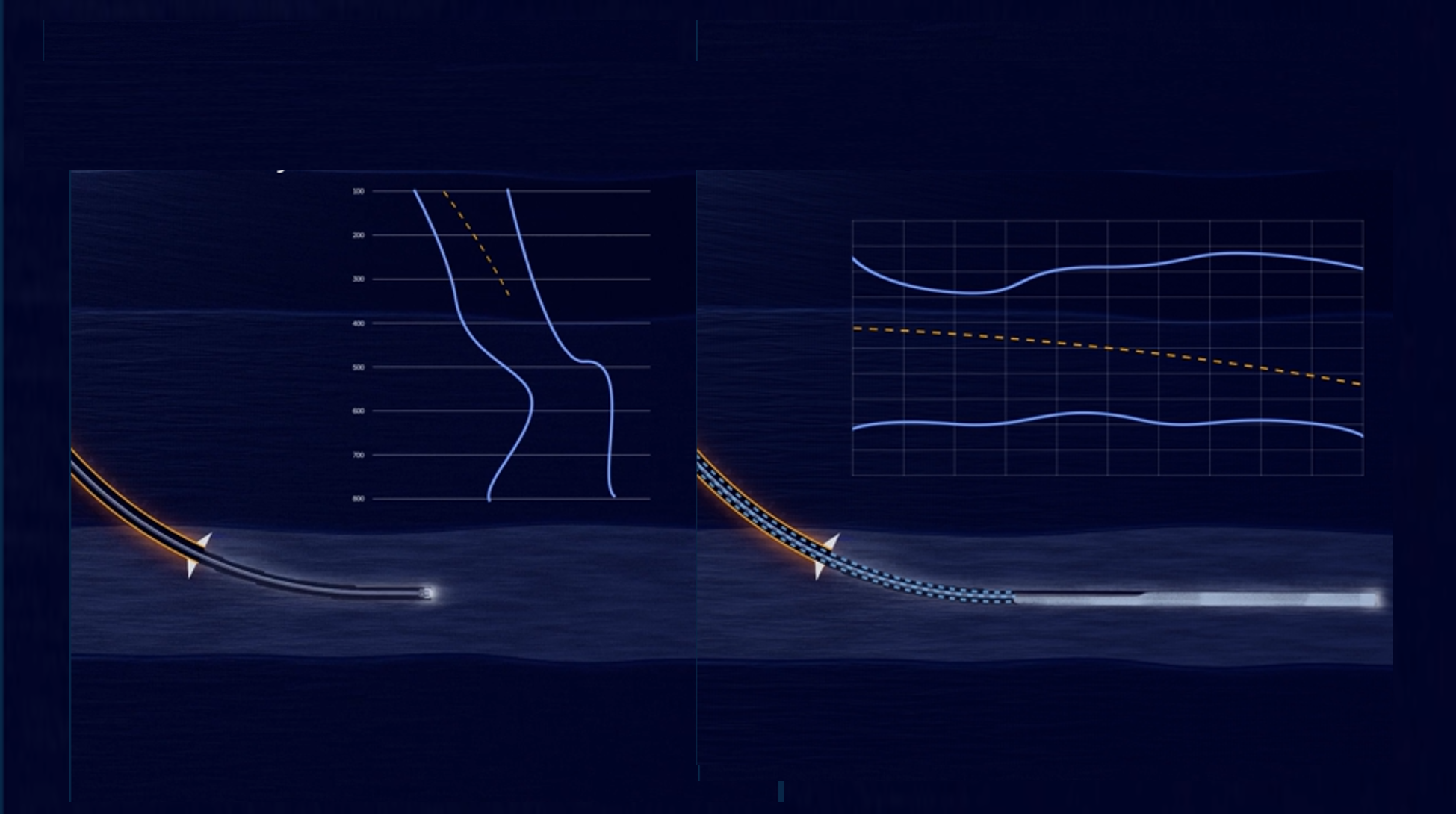

Fig 1: Tripping Speed of Screens Simulated Conventional versus EC-Drill® with Reduced Level.

(Purple Line – Tripping Speed Conventionally. Red Line – Tripping Speed with EC-Drill® reduced Fluid Level).

Fig 2: Slip to Slip (S2S) connection time while tripping drill pipe on an example EC-Drill® well.

Watch webinar: Discover EC-Drill® MPD Rig Integration Made Easy

Solution

EC-Drill® enables reducing the fluid level to compensate for the surge pressure while running pipe. Reducing the fluid level can compensate for the increase in pressure from surge. The result is the tripping speed can be increased without the surge pressure exceeding the fracture gradient and experiencing losses. The fluid level can be adjusted during tripping and connections to maintain a constant BHP or can be set to a constant level and used to verify the displacement of the screens and drill pipe.

EC-Drill® enables accurate volume control during tripping as any change in the fluid level in the riser is monitored. This improves the operator’s ability to detect any changes in the volume and respond quicker if losses or an influx occurs compared to conventional methods. No equipment or part changeout is require when tripping or with changes to the pipe size. EC-Drill® is an open system with no control device.

Additional reading: CCS, SBP, CML - A Comparison Guide

Challenge Solved

EC-Drill® was used to reduce the fluid level during running screens in 4 long horizontal sections. The result was there was no limit on the tripping speed and the rig could trip as fast as normal. Fig. 1 compares the actual tripping speed using ECDrill to the simulated conventional tripping speed with a full riser: with EC-Drill® the surge pressure is compensated for and no limit on tripping is required. Comparing the simulated conventional and actual EC-Drill® tripping speeds, EC-Drill® increased the tripping speed by 50% with an average slip to slip connection time of 1.15 min over 3000 m of tripping.Fig. 2 shows the summary of the slip to slip connections times while tripping drill pipe. The rig and crew were able to achieve Slip to Slip connection times faster then the target while using EC-Drill® to reduce the surge pressure.

The fluid level was brought down to a set level and then allowed to drift upwards as the screens and landing string is run in hole. During tripping the change in fluid level is checked against the planned steel displacement to check on changes to volume in the well.

Conclusion

- Depleted reservoir with fractured zones, high lost circulation challenges, and long horizontal reservoir sections

- Running long screens often required limiting tripping speed to reduce surge pressure

- EC-Drill® compensated for surge pressures, removing limit on tripping speed

- EC-Drill® had no effect on connection times, with an average slip to slip time of 1.15 minutes for over 3000 m EC-Drill® increases screen tripping speed by 50 per cent

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

RMR® Technology

Ormen Lange, North Sea

Read Case Study:

EC-Drill® Technology

Extending Length of Wells

Read Case Study: