Advanced Pressure Control During and After Cementing

Provides Safe Isolation of Problematic Zones

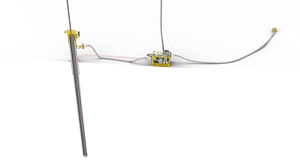

The MPC® technology allows the operator to reduce the pressure as heavier fluid such as spacer or cement slurry is displaced up the annulus. MPC® also applies pressure when the cement is curing to prevent channeling.

The result? No losses and a cement job you can depend on.

Why Operators Choose MPC®

Whether it is a weak zone with risk of losses or high-pressure zones with risk of channeling flow, MPC® have the solution. Receive verification when cement returns to seabed and barrier test the cement while it is setting. Here’s what sets it apart:

Where MPC® Makes the Greatest Impact

The MPC® technology is tailored for cementing operations in areas requiring pressure control. It provides effective cementing in weak formations and adds pressure in over pressured zones, proving essential for well integrity.

Explore where MPC® delivers the most value:

Top-Hole Challenges

The top-hole section is the structure the rest of the well relies on. Whether you’re dealing with shallow flow hazards or unconsolidated sands, MPC® ensures top of cement to seabed, pressure tested barrier and improved integrity.

Control the annulus pressure when cementing long sections.

Apply pressure when cement is curing.

Avoid adding light-weight or foam cement to your operations.

MPC® Operational FAQs

We receive a lot of detailed questions from drilling teams, and we’re always ready to support. To make things easier, we’ve gathered some of the most frequently asked questions about Managed Pressure Cementing and provided clear, practical answers below.

-1_web.jpg?width=300&name=Untitled%20design(8)-1_web.jpg)