Case Study:

EC-Drill® and RMR® Providing Large Savings for Shell

The opportunity

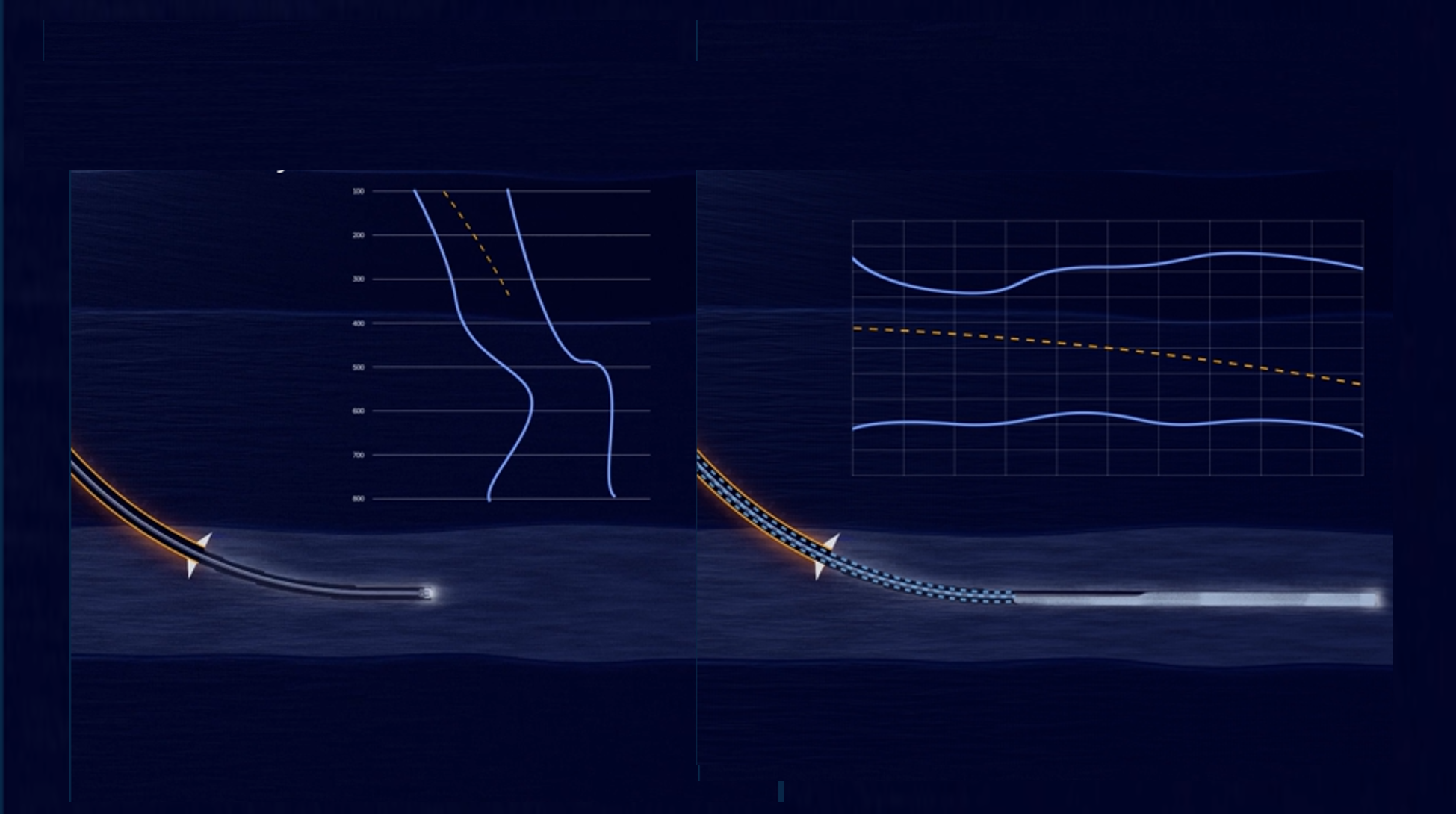

Drill and complete (gravel pack) 4 wells in the 2022 Ormen Lange drilling campaign (Norway) using Enhanced Drilled RMR and CML Technology

- Wells could not be drilled and completed using conventional (MPD) drilling technologies.

- Reservoir was depleted to 1/3 of the original reservoir pressure in ~900m of water with minimum . (equivalent mud weight of 0.4 sg)

- Combining the application of the innovative RMR&CML technology significantly reduced aggregated risk of the drilling campaign.

- Drill an exploration well with high pore pressure uncertainty

Additional reading: EC-Drill® and RMR® Drilling the Undrillable for Shell

The Technology unlocked

The integrated use of RMR enabled drilling the 26” riserless section beyond a shallow gas anomaly.

RMR enabled setting a deep 20" shoe no need for the contingency liner.

Ability to better control ECD and avoid losses in the overburden.

Achieve critical shoe depth for 13.5/8" no intermediate liner required prior to drilling through the depleted zone.

CML was a key enabler to install a gravel pack completion in WBM.

Cementing the 13 5/8 csg achieved minimum required TOC. (Simulation indicated CML was not required, but was used to de-risk the cement operation)

Quick dynamic bottom hole pressure control improved well control and enabled drilling through depleted zone

Excellent operating efficiency related to circ subs with high flow rate and tripping with tight swab/surge margins.

No losses & associated OBM & NPT cost.

This was a breakthrough technology that allowed to successfully drill these wells, which a few years ago we thought were not possible to drill and complete” [Production Technology Technical Authority]

The result

Drilling and gravel packed these wells with very tight pressure margins.

Saved ~80% on the completion RIH/POOH time

RMR&CML provided significant operational risk mitigation, no losses and contributed to the cost reduction achieved.

The technology unlocks development targets previously considered impossible.

Achieved critical TOC to secure Longterm well integrity.

The CML worked very well and is a super great technology to be able to drill these highly depleted reservoirs, which only a couple of years ago were not drillable. [Well Operations Team Lead]

Learn more about the EC-Drill® and RMR® and why they're chosen by operators.

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

EC-Drill® Technology

Instant Kick Detection Demonstrated on Deepwater Well

Read Case Study:

EC-Drill® Technology

Dual Gradient in Gulf of Mexico Deepwater

Read Case Study: