Elevate Well Monitoring

Precision Monitoring

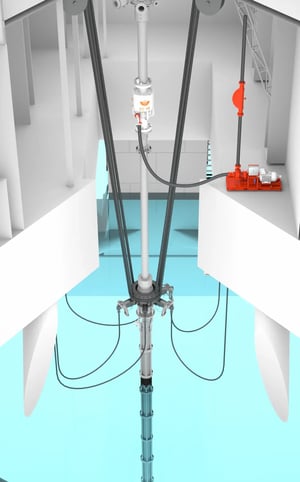

EC-Monitor™ acts as an inline trip tank, absorbing volume fluctuations and providing real-time, accurate volume control directly on the well. This enables precise overwatch, removing uncertainties associated with well monitoring

Why Operators Choose EC-Monitor™

EC-Monitor™ reduces uncertainties associated with other Kick and Loss Detection Systems and provides near Instant detection of anomalies. The cognitive load on drillers is minimized, facilitating a step towards automated well control and enhancing overall process safety.

Here’s what sets it apart:

Where EC-Monitor™ Makes the Greatest Impact

EC-Monitor™ is tailored for scenarios demanding meticulous control and rapid response in drilling operations. It excels in environments where early detection of kicks and losses is important. This tool is particularly effective in harsh offshore environments, where its precise monitoring capabilities eliminates uncertainties with volume control.

Explore the scenarios where EC-Monitor™ delivers the most value:

Pressure Management Challenges

In narrow operating windows where margins are small with a higher risk for taking losses or having gains, reliable monitoring is essential. EC-MonitorTM provides unmatched volume control regardless of the operation is drilling, tripping or cementing.

Quickly identifies discrepancies in fluid volumes indicating losses.

Precise control and monitoring of volume directly on the well for reliable and near instant feedback on anomalies when operating in environments with heighted risk for gains or losses.

Deepwater & Ultra-Deepwater

In offshore drilling such as deepwater environments, rig motion such as heave generates uncertainties in well monitoring. Monitoring volume in surface lines and pits leads to delayed information of events in the well during non-circulating operations. The EC-Monitor™ offers enhanced monitoring capabilities directly on the well enabling near instant detection of volume anomalies.

Early and accurate detection of fluid volume changes, allowing for prompt corrective action to maintain well control.

See how Enhanced Drilling’s technologies deliver impact where it matters most.

EC-Monitor™ Operational FAQs

We receive a lot of detailed questions from drilling teams, and we’re always ready to support. To make things easier, we’ve gathered some of the most frequently asked questions about EC-Monitor™ and provided clear, practical answers below.

-1_web.jpg?width=300&name=Untitled%20design(8)-1_web.jpg)

Planning a Challenging Well?

Let’s discuss how the EC-Monitor™ can improve volume control and early Kick and Loss detection that is not effected by heave. Our experts are here to help.