Enhance Drilling with Eco-Efficiency

Zero Discharge, Enhanced Control

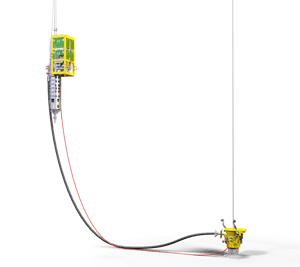

The RMR® technology revolutionizes top-hole drilling with its innovative, eco-friendly approach. By employing a seabed pump and a Suction Module at the wellhead, it efficiently recovers and recycles mud, cuttings, and debris, preventing any discharge into the ocean. This process not only preserves marine environments but also enables the use of an engineered fluid for addressing top hole challenges.

The technology ensures stable, quicker, and safer drilling operations, significantly reducing environmental impact and optimizing well integrity.

Why Operators Choose RMR®

Designed for optimal efficiency and environmental stewardship, the RMR® technology is the go-to technology for operators aiming to tackle the complexities of top-hole drilling. Here’s why it stands out:

Where RMR® Makes the Greatest Impact

The RMR® technology is specifically designed to excel in challenging top-hole drilling scenarios. It enables pushing the surface casing deeper, effectively manages shallow flows and wellbore instability, removes environmental impact and improves the overall safety and efficiency of drilling operations. This makes it particularly valuable in environments where traditional drilling methods may fall short, such as managing instability challenges or at sites requiring stringent environmental compliance.

Explore where the RMR® technology delivers the most value.

Top-Hole Challenges

The top-hole section sets the premises for the entire well. Addressing top-hole challenges such as instability, shallow flows and unconsolidated formations while ensuring there is no debris around the wellhead area is crucial.

Prevent chemical and mechanical wellbore instability challenges with a proper drilling fluid.

Eliminating logistic challenges and environmental concerns.

Enabling volume control resulting in the ability to monitor the well and detect any gains or losses.

Prevents any discharge into the sea but also allows for continuous monitoring of well conditions.

Environmental & Regulatory

Enhanced Drilling’s technologies support operators in meeting the industry’s strictest environmental standards. From eliminating discharge to reducing logistics and operational waste, we help you minimize environmental impact while maintaining performance.

Combine sections to save a casing run and cement job.

Enable a circulating system and combine sections.

Remove a section, reduce transportation, and prevent dumping.

Enabling zero-discharge operations, ensuring no pollutants enter the marine environment.

RMR® Operational FAQs

We receive a lot of detailed questions from drilling teams, and we’re always ready to support. To make things easier, we’ve gathered some of the most frequently asked questions about Riserless Mud Recovery and provided clear, practical answers below.

The maximum water depth for RMR® depends on pump capacity, which is determined by the intended flowrate, ROP, hole size, and fluid density.

When RMR® is combined with EC-Drill®, the SPM can also be deployed on a hard pipe that doubles as the MRL.

-1_web.jpg?width=300&name=Untitled%20design(8)-1_web.jpg)