Build a Better Foundation.

Top-hole solutions that set your entire well up for success.

Enhanced Drilling’s top-hole technologies help you drill longer, cleaner, and safer from day one — while protecting the environment and reducing risk in the most fragile part of the well.

Why the Top-Hole Section Is Where It All Begins

The top-hole is more than just the starting point — it’s the foundation of the entire well. Poor conditions, shallow hazards, or environmental restrictions can compromise well integrity from the beginning. Enhanced Drilling helps operators overcome these challenges with a closed-loop, riserless system that reduces cost, risk, and environmental impact.

Looking to explore the next phases of the well lifecycle?

Top-Hole Value We Deliver

Addressing drilling challenges, adding safety benefits and combining sections – Enhanced Drilling covers all your needs for top-hole drilling.

Where We Solve Real Problems

Top-hole operations often have fragile conditions — from shallow flows to unstable formations. Enhanced Drilling’s solutions are designed to address these challenges directly, delivering safer, cleaner and more predictable operations where it matters most.

Key application areas where we add value:

The Technology Behind the Advantage

Our top-hole performance is made possible through proven and field-tested technologies that work together to control pressure, recover fluids, and optimize operations while protecting the environment. These are the systems that power our top-hole value creation.

CTS

Efficient Cuttings Removal

The CTS technology streamlines cuttings removal and ensures compliance with local regulations by discharging cuttings away from any environmentally sensitive areas, reducing the ecological footprint and safeguarding marine habitats.

The design enables easy installation and will prevent debris from accumulating on and around the wellhead area by pumping away all returns during top-hole drilling.

RMR®

Zero Discharge, Enhanced Control

The RMR® technology revolutionizes top hole drilling with its innovative, eco-friendly approach. By employing a seabed pump and a Suction Module at the wellhead, it efficiently recovers and recycles mud, cuttings, and debris, preventing any discharge into the ocean.

This process not only preserves marine environments but also enables the use of an engineered fluid for addressing top-hole challenges.

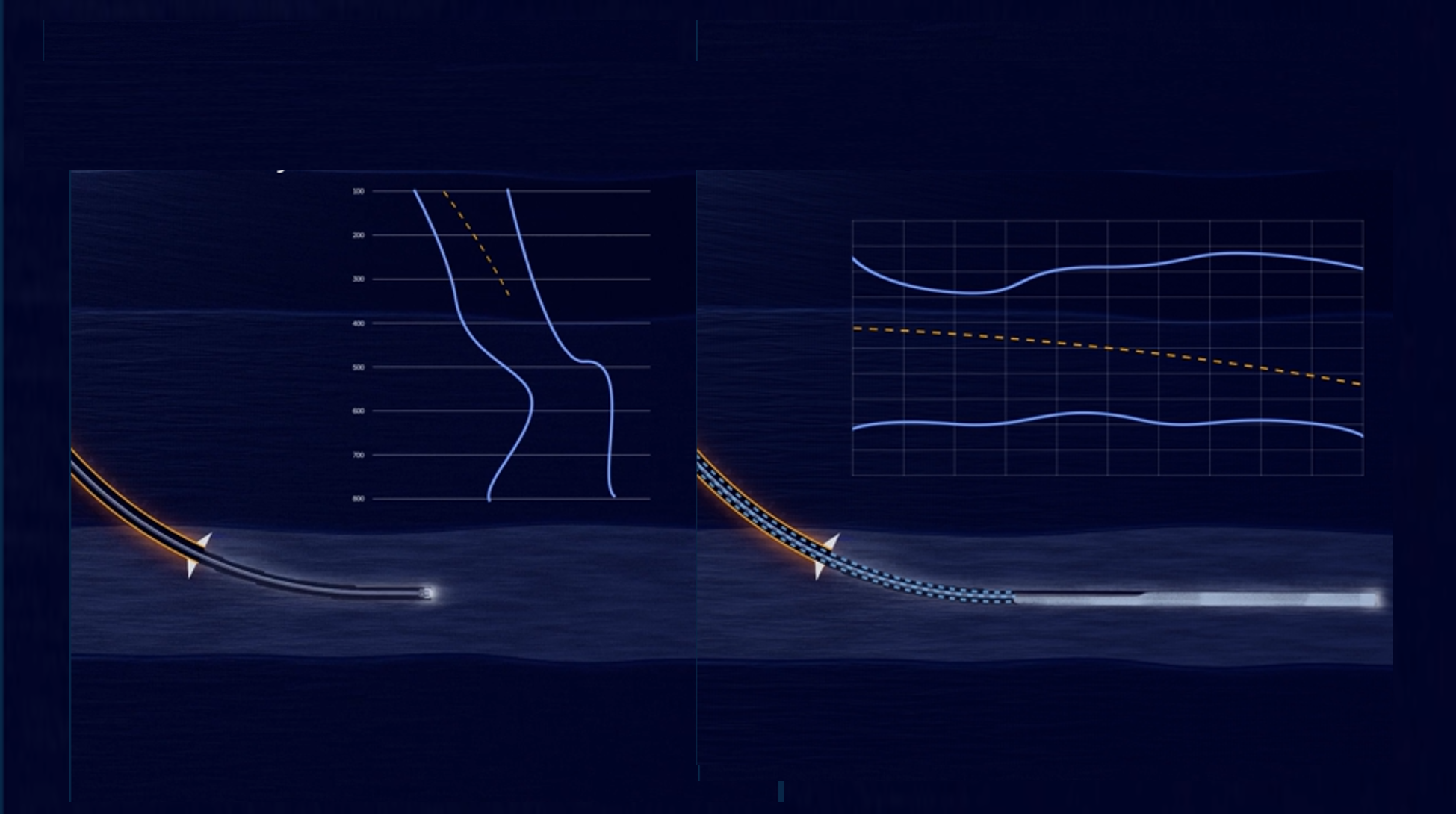

MPC®

Advanced Pressure Control During and After Cementing

The MPC® technology allows the operator to reduce the pressure as heavier fluid such as spacer or cement slurry is displaced up the annulus. MPC® also applies pressure when the cement is curing to prevent channeling.

Whether it is a weak zone with risk of losses or high-pressure zones with risk of channeling flow, MPC® have the solution.

-1_web.jpg?width=300&name=Untitled%20design(8)-1_web.jpg)