Case Study:

EC-Drill® Dual Gradient in Gulf of Mexico Deepwater

Key Challenges

- Narrow Operating Window

- Complex well architecture

- High drilling cost

- Long lasting drilling operations

Benefits

- Simplified well design

- Reduced operational time

- Save on less casing strings

EC-Drill® eliminating casing strings as a standard approach in deepwater drilling

Challenge

Reducing casing points in Deepwater Drilling.

A common challenge for Deepwater wells is the need for multiple sections.

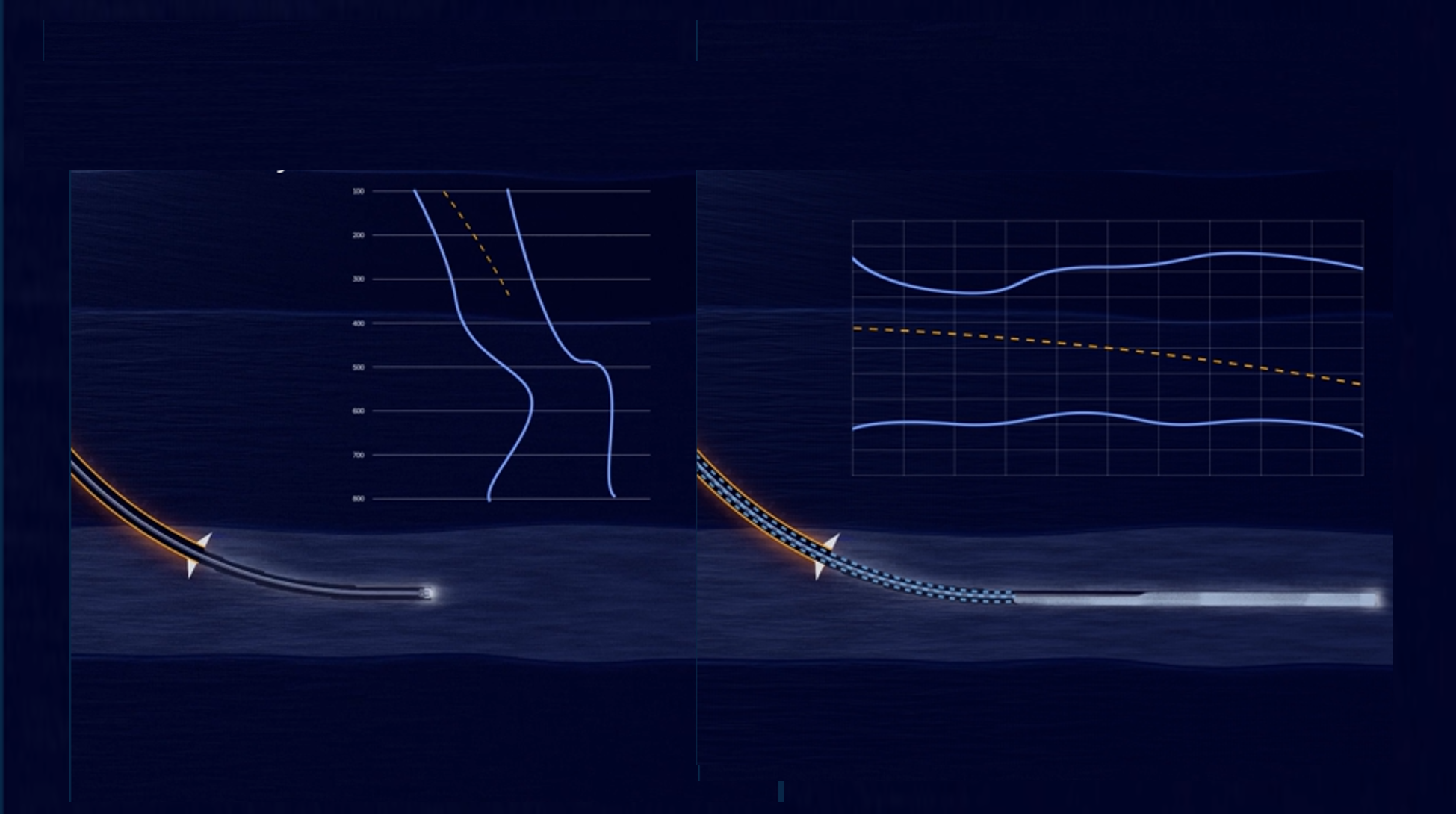

Plot 1: Example of Deepwater Window and resulting Casing Shematic.

The narrow operating envelope in deepwater wells requires frequent casing/liner setpoints which makes the well design more complex. The casing/liner strings comes at a high cost by themselves, and the wells take longer to complete

Additional reading: EC-Drill® Dual Gradient in Gulf of Mexico Deepwater

Solution

EC-Drill® takes advantage of the Dual Gradient effect it creates when lowering the Riser Level – and the starting point of the fluid column. The resulting pressure profiles in the well matches the trend of the operating window enabling the sections to be extended. In addition to eliminating a liner/casing the sections can in some cases be drilled conventionally by keeping the riser level fixed at a reduced level removing the need to operate with a Constant Bottom Hole (CBHP) approach.

Plot 2: Examples of benefiting from the Dual Gradient Effect

Challenge Solved

EC-Drill is now used to eliminate Liner/Casing strings as a standard approach by benefiting from the Dual Gradient effect it creates. The wells are planned and executed accordingly which simplifies the well design and reduces the time to drill and complete them. The extended sections can in some cases be drilled conventionally going beyond the CBHP approach. Even with Fracture Gradients at the shoe being lower than the Pore Pressure further down in the section it is straightforward to drill and complete the sections.

Watch webinar: Explore how EC-Drill® Dual MPD is putting an end to the need for frequent casings and liners, thanks to the Dual Gradient effect in this webinar.

Conclusion

- EC-Drill established eliminating Casing/Liner in Deepwater drilling as a standard approach by utilizing the Dual Gradient Effect.

- EC-Drill enables drilling in negative operating windows

- EC-Drill proven as both enabler and optimizer

- EC-Drill “more than MPD” going beyond only CBHP approach

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

EC-Drill® Technology

Instant Kick Detection Demonstrated on Deepwater Well

Read Case Study:

EC-Drill® Technology

Troll field, North Sea

Read Case Study: