Case Study:

EC-Drill® Improves Production from Gas Producer

Project

A gas well offshore Norway was re-drilled after underperforming at only 10% of expected output. By using EC-Drill® to manage bottom-hole pressure during drilling and gravel pack completion, the operation avoided losses and increased production by five times.

Key challenge

In a depleted field with low horizontal stress and poor initial production, the goal was to overcome fluid losses and achieve a full Alpha-Beta wave gravel pack.

Improve production from Gas Provider

One well was drilled and completed offshore Norway. The gas rate from the production test was disappointing, as the well only produced about 10% of expectations. The reservoir section was drilled with a 1.05sg OBM. The drilling window ranged from 0.99sg (well bore stability) to 1.17sg (minimum horisontal stress). The lower completion was with stand alone sandscreens.

Due to the disappointing production rate, it was decided to re-drill and make a gravelpack lower completion using Water based mud - a concept successfully used previously on the field with EC-Drill®.

During drilling and completion there would be a high risk of losses, since the lightest available WBM drilling mud and brine was 1.20 sg. which is higher than the expected minimum horizontal stress. Making a successfull open hole gravel pack would not be possible, due to losses since the formation would be fractured.

EC-Drill® as solution

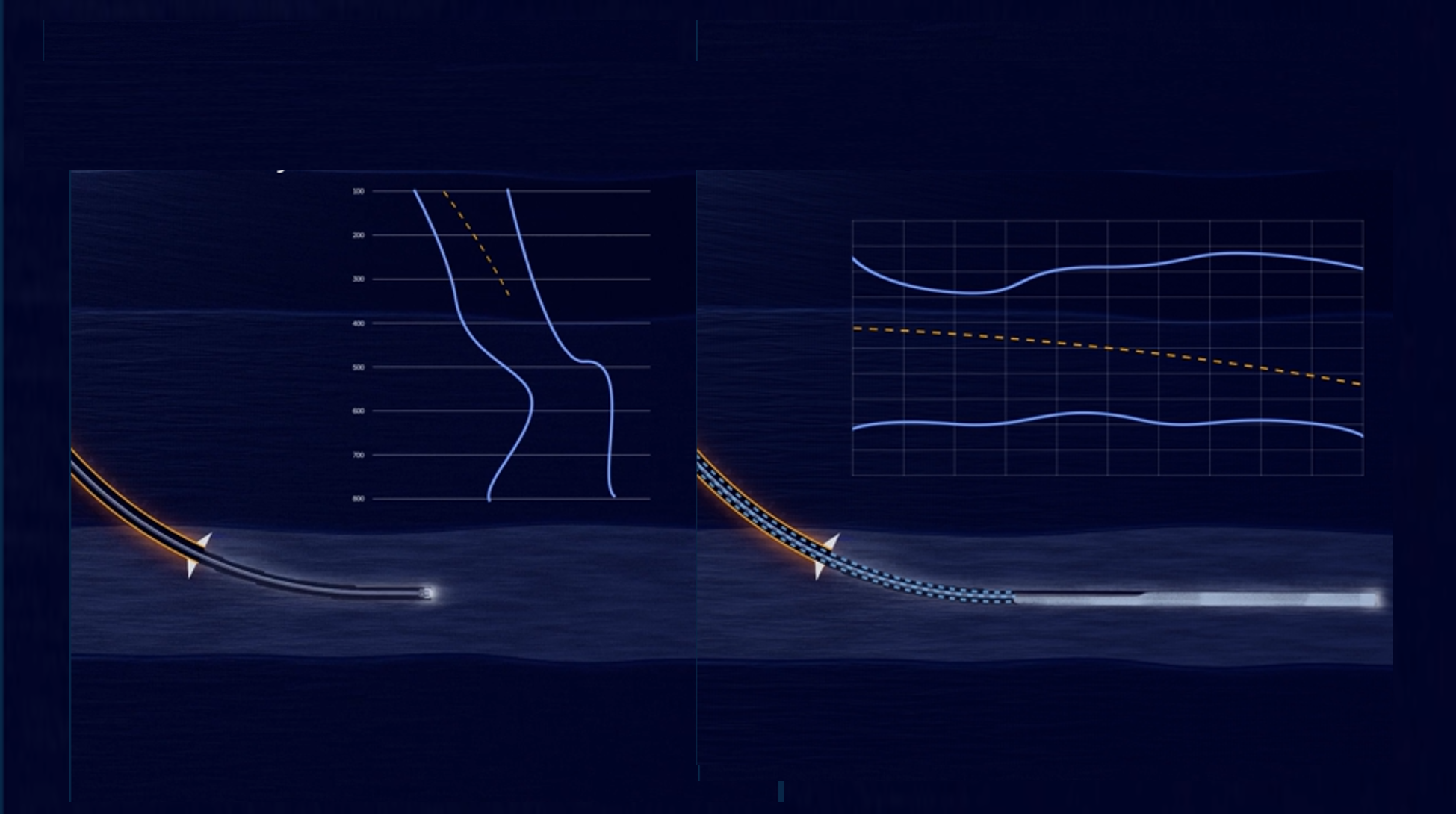

The solution was to use EC-Drill®, which reduced the effective mud weight by reducing the mud level in the riser. For the re-drill the mud level was reduced to 382m below RKB which brought the Equivalent Mud Weight (EMW) down from 1.20sg to 1.03sg. This reduction in riser level effectively prevented any losses while drilling and during pumping of the gravel pack.

The gas production test after completing the well with gravelpack and Controlled Mud Level (CML) was successful. The initial gas production test was limited by the size of the flare, so the maximum flow capacity was at this point unknown. Results from this first limited test showed the gas rate was still 5 times larger than the original well.

Learn more about the EC-Drill® here.

Challenge solved

The well was drilled and completed with EC-Drill® while facilitating the use of a higher density water-based drill-in fluid and Gravel Packing as completion method.

The re-drill was faster and without losses when using EC-Drill and gave an increase of more than 5 times the original well when production testing.

EC-Drill® is now used consistently for gravel packing.

Benefits

- Drill in depleated field

- Eliminate losses

- Use desired Drill-in and Completion fluid

- Increased production

Conclusion

- EC-Drill® enabled drilling in depleted field

- EC-Drill® reduced operational time and prevented losses

- EC-Drill® facilitated the use of a water-based drill-in fluid

- EC-Drill® facilitated using gravel pack as completion method

- EC-Drill increases production when used for completion

Curious to learn more about the benefits of the EC-Drill®? Have a look at this webinar, presenting case histories from global operations.

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

EC-Drill® Technology

Troll field, North Sea

Read Case Study:

EC-Drill® Dual MPD Technology

Influx Management

Read Case Study: