Case Study:

EC-Drill® – Extending Length of Wells

Key Challenges

- Weak sand reservoir

- Low pressure

- Fault zones prone to losses

- High lost circulation

Benefits

- Unlocking reserves

- Reducing ECD

- Reducing lost circulation

- Extending length of wells

- Saves mud volume and cost

Challenge

Depletion on the Troll field requires long MLT horizontal wells through weak sand reservoir to maintain production.

The Troll wells are designed as long horizontal MLT wells through a thin sand reservoir with low pressure.

The sand reservoir has become depleted over many years of production, resulting in a lowered fracture gradient, in addition to fault zones that are prone to losses. As a result, seepage losses and severe lost circulation events became a growing challenge during drilling, especially as the 8 ½” laterals were extended. The water based mud weight is between 1.05 and 1.07 sg and cannot be lowered any further. The low reservoir pressure and constant depletion rates limit the drilling window and the lateral lengths that can be achieved conventionally. To reach new reserves and prolong the life of the field the lengths of the wells needed to be extended.

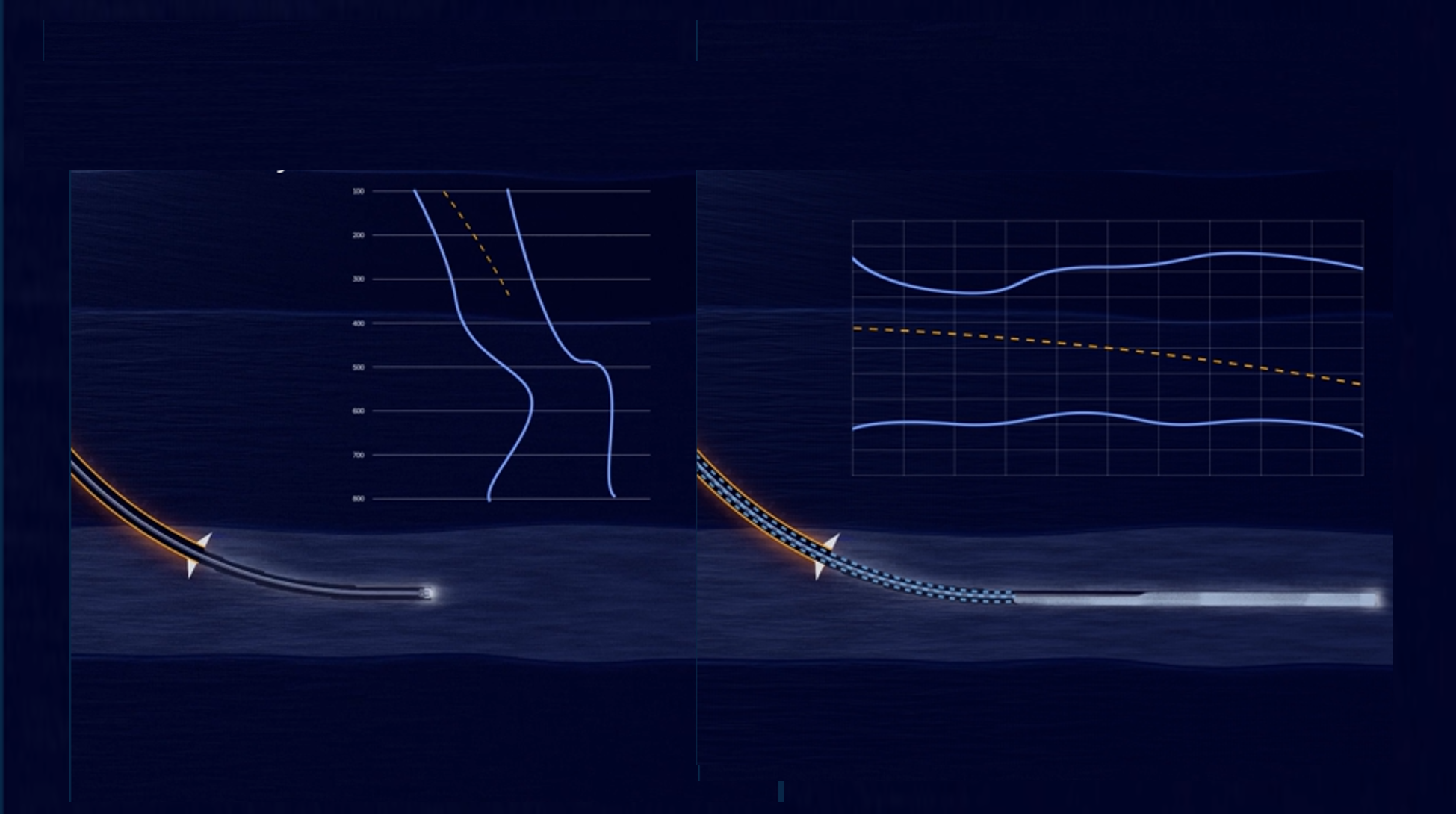

Figure: Average yearly length of wells using EC-Drill®

Watch webinar: How to Simplify Well Design and Enhance Your Drilling

Solution

EC-Drill® allows the operator to monitor and adjust the fluid level while drilling. The fluid level can be lowered to reduce the ECD and reduce losses to formation. The ECD can be reduced to below the minimum 1.05 sg mud weight and that enables the operator to avoid or reduce losses to an acceptable rate to drill the planned lateral lengths of the well. During drilling operations EC-Drill® accurately monitors the fluid level and will quickly alert the operator if there is a change in volume, detecting if a loss and gain is occurring quicker then conventional methods.

The detection abilities enable the operator to respond quickly to changes in volume. For instance, if losses occur the operator can reduce the BHP in minutes to stop the losses and continue drilling. EC-Drill® can be used during drilling, tripping, with different sized drill pipe, and no pipe in hole with out requiring any changeout of equipment.

Additional reading: EC-Drill® Instant Kick Detection Demonstrated on Deepwater Well

Challenge Solved

EC-Drill® has been used to reduce the fluid level during drilling to prevent the ECD from exceeding the fracture gradient and going on losses. The operator has been able to extend the length of the wells on the Troll field by over 3,500 m MD since implementing EC-Drill in 2014 as shown in Fig 1. The average well length when ECDrill® was first introduced on Troll in 2014 was 5,430 mM MD. The well length steadily increased each year when using EC-Drill® and in 2021 reached 8,940 m MD. Targets that in earlier wellbores could no be reached, have been successfully penetrated with CML, unlocking valuable reserves.

In addition, EC-Drill® has reduced the volume of mud lost to formation, saving the operator cost and logistical volume requirements for each well.

The result is EC-Drill® has been a key tool for the operator to extend the life of the Troll field and will continue to play an important role as the wells continue to reach record lengths.

Conclusion

- Low pressure and depleted reservoir with faults, high lost circulation challenges, and long horizontal reservoir sections

- EC-Drill® enabled reduction in ECD to avoid losses while drilling long horizontal holes

- EC-Drill® assisted operator in extending the length of the wells by an average of 3,500 m MD from 2014 to 2021, unlocking valuable reserves

- EC-Drill® reduced mud losses and saved operator the associated cost

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

RMR® Technology

BP, Egypt

Read Case Study: