Case Study:

EC-Drill® Dual MPD Influx Management

Key Challenges

- Narrow Operating Window

- Influx Management in Deepwater

- High drilling cost

- Long lasting drilling operations

Benefits

- Reduced operational time

- Save on less casing strings

EC-Drill Dual MPD System safely circulating out influx with zero operating margin in Deepwater well.

Challenge

Safely circulating out an influx in a Deepwater well with zero operating margin. Influx management in Deepwater wells are challenging. The friction from the long Chokeline makes it difficult to circulate out gas without exceeding the fracture pressure while other well control methods are time consuming.

A deepwater Operator wanted to use EC-Drill® to benefit from the Controlled Mud Level (CML) MPD while drilling, and at the same time being able to manage any influxes by circulating them out of the well with MPD.

Watch webinar: Deepwater MPD | Introducing EC-Drill ® Dual MPD

Solution

EC-Drill® Dual MPD combines the two MPD methods CML and SBP. Added to the original EC-Drill® system is a Dual Annular placed in the riser above the outlet to the Subsea Pump Module (SPM), and MPD chokes on the surface. It enables circulating out an influx using two different approaches without resorting to conventional well control methods.

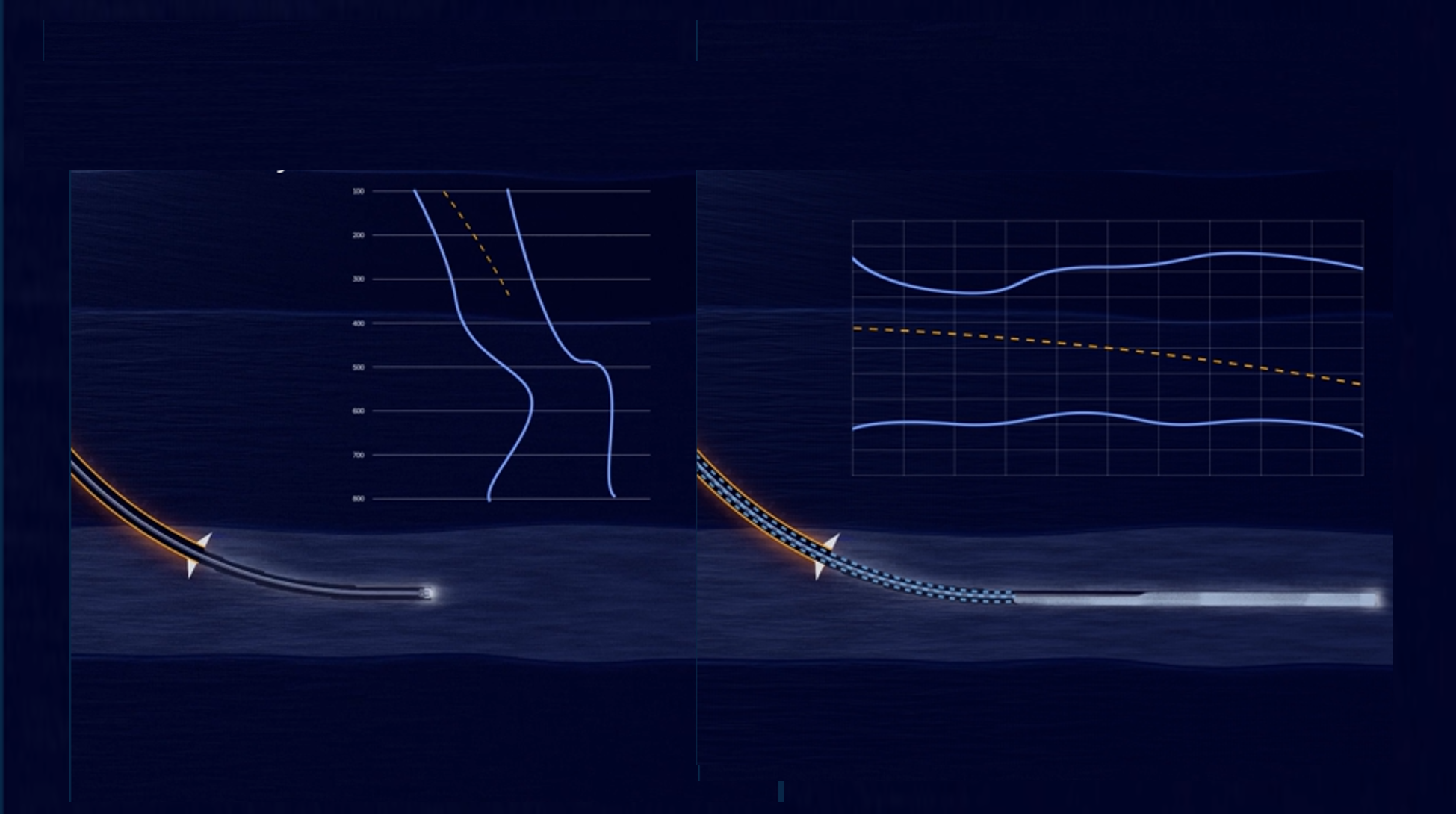

One option is to circulate out the influx using only the surface choke to control the influx (figure on the left). The SPM is bypassed and the added fluid column up to the rig reduces the required back pressure enabling larger size influxes to be controlled while exerting less pressure on the open hole and surface equipment. The other option involves using the SPM to control the influx (figure on the right) while lifting the fluid up the Mud Return Line. This reduces the pressure in the well to stay below the Fracture Gradient while the influx is circulated out.

Plot 1: Simplified schematic of the two methods

Plot 2: Pore pressure came in at 11.05ppg while staying below 10.8ppg at Shoe

Challenge Solved

While utilizing the Dual Gradient effect generated by the EC-Drill® system to drill in a zero operating window an influx occurred. The instant kick detection system enabled rapid reaction and the BOP was closed showing an increase in Wellhead pressure of 68psi. The Dual Annular was closed and the surface MPD choke set to hold 100psi to prevent any sluggish flow up the Mud Return Line. The Riser Pressure setpoint was set to 25psi above the Wellhead pressure as a safety margin. The BOP was then opened, and the SPM maintained a constant Standpipe pressure while safely circulating out the influx.

The Riser Level above the Dual Annular was adjusted according to the actual well conditions before opening the Dual Annular. The well was again overbalanced without the need for a 2nd circulation to displace in heaver drilling fluid enabling operations to quickly resume.

Conclusion

EC-Drill® providing unique Early Kick and Loss Detection

- EC-Drill® Dual MPD safely performed influx management without exceeding the fracture pressure in a zero-operating window.

- Only one circulation required before resuming operations.

- EC-Drill® proven as both enabler and optimizer

- EC-Drill® “More than MPD” going beyond only a CBHP approach

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

RMR® Technology

BP, Sakhalin Island

Read Case Study:

EC-Drill® Technology

Dual Gradient in Gulf of Mexico Deepwater

Read Case Study: