Case Study:

RMR® – BP Egypt

Project

Enhanced Drilling provided Riserless Mud Recovery (RMR®) services to BP Egypt in 2008 so that a deep 22” surface casing could be set, despite a weak conductor.

Key words

- Top-hole stability

- Deep surface casing

- Riserless drilling with mud returns

- Reduced risk in drilling

- Simple solution to major problem

- RMR® on Jack-up rig

RMR® a success from the start on Egypt Jack-Up

How could BP achieve a record service depth?

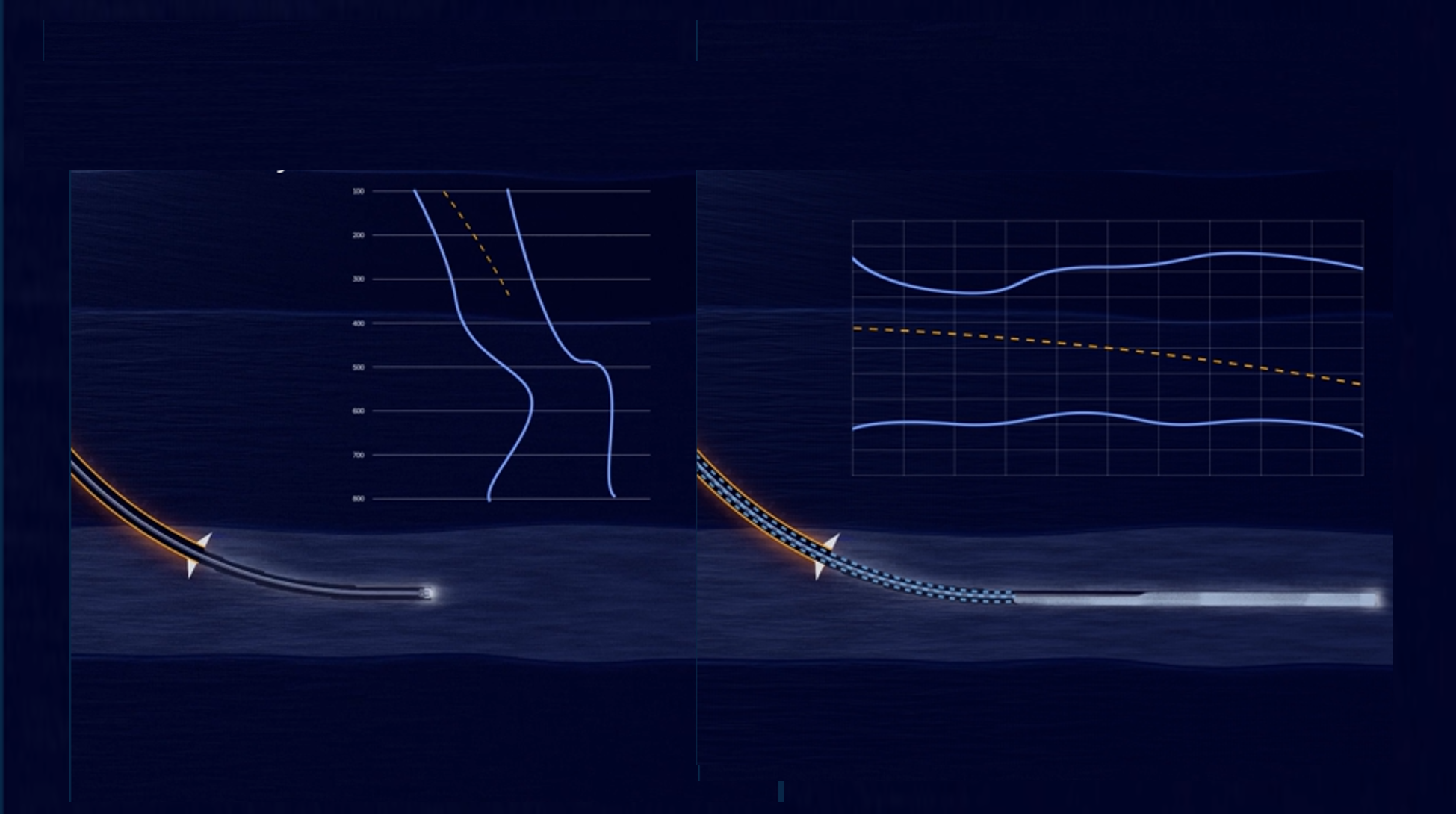

BP Egypt wished to install service casing at about 1,085m (3,560ft) in order to achieve its well objectives. However, there was firm sand preventing the conductor from being driven deeper than about 50m (165ft) below the mudline (BML). The water depth at the location is only about 19m (62ft) and the Constellation II rig has a large air-gap of approximately 40m (131ft). These factors combined to produce a weak conductor shoe (low fracture gradient).

It was calculated that the conductor shoe would only support a mud weight of 0.8SG (7ppg) back to the rig floor. This meant that the next section could not be drilled conventionally with seawater, let alone with the 1.13SG (9.4ppg) inhibited mud that was required for hole stability in the next section. There was also a requirement for Fluid Loss Control to control the losses into the permeable sands. (See Case Study 2 for the RMR® solution to problems caused by water destabilising shallow sands).

If the casing program of a close offset well had been used, a 16” liner would have been required. This would mean additional time for under-reaming two hole sections, as well as running and cementing the 16” liner. The additional operations were estimated to take 10-20 days and cost between $5m-10m. It would have been possible to have an outlet in the conductor below the sea level and to drill without returns to the rig. However, this was not a practical option due to the environmental concerns and cost of dumping very large amounts of mud to the sea and the problems of supplying these large volumes of inhibited mud.

Additional reading: Case study: RMR® INPEX, Browse Basin

Another BP/Enhanced Drilling winning combination

BP was the first user of Enhanced Drilling’s RMR® system (see Case Study 1). It was also the first company to use the system for environmental reasons in the Sakhalin Island area (see Case Study 3). BP saw that subsea pumping could provide the solution to the Rahamat-1 well. It turned to RMR® for drilling operations. RMR® would take the mud returns from an outlet at sea level and pump the mud back to the rig. This would remove the effect of the large air gap and allow inhibited mud to be used in the next section.

Installation of the RMR® system

Standard RMR® equipment was modified for this operation. The Suction Module was replaced by a docking port directly onto the conductor at sea level and the pump was landed on the seabed. With this method, there were no subsea connections and an ROV was not needed. Running the RMR® equipment was part of the conductor-running operations and took little or no extra time.

/RMR/BP%2c%20Egypt.png?width=983&height=637&name=BP%2c%20Egypt.png)

Watch webinar: Combined Services: How one system can perform three services.

Drilling of Rahamat – 1

The conductor was driven to 51m (167ft) below mudline. The RMR® system was installed and the 26” hole section drilled with inhibited water-based mud. There were mud losses into coarse sands and these were cured by the addition of Fluid Loss polymers and LCM (Lost Circulation Material) without significant lost time. There was no breakdown at the conductor shoe.

With mud from sea level down and air above, the ECD (Equivalent Circulating Density) at the conductor shoe was reduced by 0.4SG (3.5ppg). Therefore, there was no fracture at the conductor shoe. This is compared to having the mud filling the conductor all the way back to the rig. The reduction in ECD at section TD was 0.04SG (0.3ppg). The 22” surface casing was run and cemented conventionally while controlling the fluid level at sea level with the RMR®. There were no losses. The casing depth of 1,085m (3,560ft) is a record depth for surface casing in the area.

Conclusion

This operation demonstrates that RMR® is not just a tool for floating rigs. The subsea pumping philosophy can be used to make top-hole drilling safer, more efficient and cheaper in all areas with shallow geohazards – regardless of whether the drilling unit is a semi, Jack-up or even fixed platform. With good planning and close cooperation between operator and service provider, using RMR® should not take any extra time.

“With the 22” casing at this depth, there was no need to use the 16” liner, saving 10-20 days rig time, or $5m-10m (based on previous well). This has the potential for an industry impact in other areas with shallow geohazards and fixed installations.” Edvin Kvalvaag – Engineering TL, BP Egypt

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

MPC® Technology

BP, Caspian Sea: Cement 22" Surface Casing and isolate notorious sands

Read Case Study:

EC-Drill® Dual MPD Technology

Influx Management

Read Case Study: