Case Study:

RMR® – CNR UK North Sea

RMR® - the simple solution to top-hole instability problems

Project

Enhanced Drilling provided RMR® services to CNR UK for the ongoing development of the Northern North Sea assets in 2007

Key words

- Tophole Stability

- Solution to hole problems

- Riserless drilling with mud returns

- Reduced risk in drilling

- Simple solution to major problem

Summary

CNR had serious hole instability problems with stuck pipe leading to well abandonments. Enhanced Drilling provided the Riserless Mud Recovery (RMR®) system so that a closed system with full specification mud could be used, with the RMR® pumping mud back to the rig. This resulted in a stable hole with no problems and the fastest 20” casing run. RMR® was cost effective on a single well and would produce greater savings on a batch setting job.

The problem

CNR drilled subsea wells in 2006/2007 as part of the ongoing development of their Northern North Sea assets. The top-hole sections, for 30” conductor and 20” surface casing, were batch set. Of the eight wells spudded, four did not achieve their objectives and were abandoned. In cases (see Table 1) AA, AB and AE the drill string stuck while, in the case of BB, the 20” casing stuck and could not be retrieved.

On the first well, BA, the 26” drilling assembly stuck at 1,200ft (366m) and the hole packed off completely with no warning. After backing off the drill string, open-ended drill pipe was washed to bottom past the fish without difficulty. The drill string was fished out with an overshot and the 20” casing run. The seabed rose approximately 6ft around the wellhead due to the large volume of cuttings pumped from the well.

/RMR/CNR%20UK%20North%20Sea_1.png?width=833&height=393&name=CNR%20UK%20North%20Sea_1.png)

Table 1: Final well tally with four ‘junked’ wells.

Additional reading: Case study: Successful use of RMR® in 2,034ft (620m) water depth.

The solution

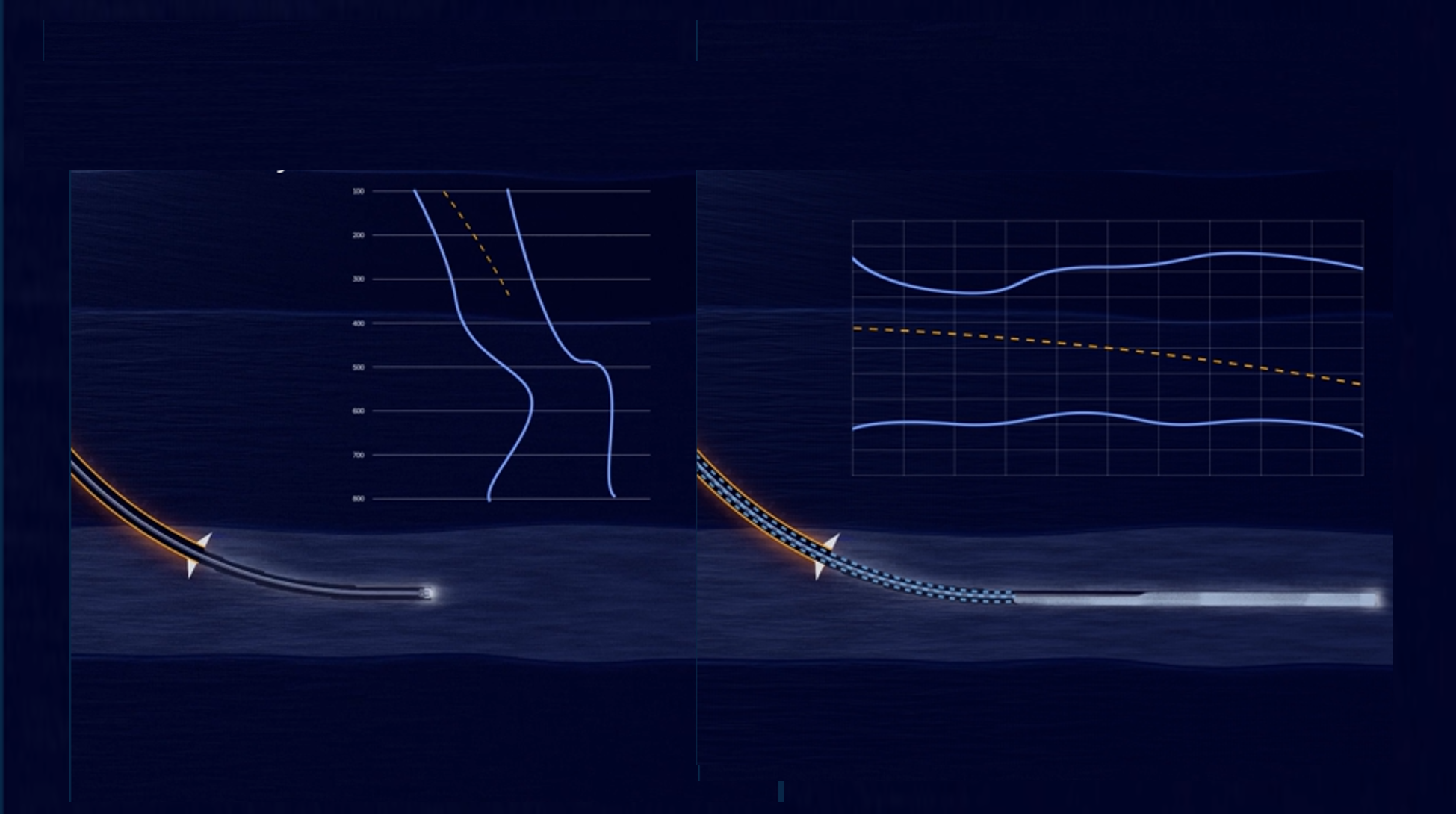

RMR® was used on well AD (see Table 1). The 26” section was drilled, and the 20” surface casing run, without any hole problems. The Suction Module (SMO) was installed on the Low Pressure wellhead using drill pipe. The 26” section was then drilled with full-specification mud. As the mud level reached the SMO, the RMR pump was used to pump the mud and cuttings up a mud-return line to the rig shale shakers for re-use. The mud/seawater interface was observed in the SMO with cameras. A weighted (9.1ppg) mud was used to start drilling.

Circulation was lost at 1,268ft, a similar depth to where the first problems in the previous wells were encountered. The mud weight was reduced and Lost Circulation Material (LCM) added to the mud. Drilling continued with 8.9ppg mud and manageable losses of approximately 30bbls/hour to the planned casing point.

There was no tight hole on the trip out so no wiper trip was needed. The casing was run to bottom, with no hole problems, in record time.

Cause of the problem

The results of the RMR® well helped CNR’s engineers understand the causes of the problems in the 26” section. There are massive, unconsolidated, high-permeability sands below 950ft (290m). Water ingress destabilised the sands, either through fractures or porosity. The sand then collapsed or ‘flowed’ into the well bore. This could occur suddenly with the sand trapping the pipe and packing off the annulus. However, the loose sand could easily be washed out with a jetting run.

The RMR® system allowed fully engineered mud to be used in the top hole with returns to the rig. The mud had a lot of fluid-loss control additives and LCM to minimise whole mud losses to the formation. This prevented water ingress and kept the sand stable. Drilling, tripping and casing-running operations were problem-free and quick.

/RMR/CNR%20UK%20North%20Sea_2.png?width=832&height=646&name=CNR%20UK%20North%20Sea_2.png) Subsea Pump Module.

Subsea Pump Module.

Future improvements with RMR®

It was also found that the high pump rates of 1,200gpm (4,500lpm), used previously with seawater, were not required. With RMR® and a closedmud system, 500gpm (1,900lpm) was enough to clean the hole of cuttings. A stable gauge hole was drilled, so no wiper trips were required. All cuttings were returned to the rig so there was no build up of drill waste around the well head, requiring rig time to jet away.

Using RMR® on a single well was cost effective. Using it as part of a batch setting operation could be significantly cheaper and more efficient than drilling with seawater. If RMR® was part of the original well planning, the 20” shoe could be pushed much deeper with the knowledge that the hole would remain stable. With a stable gauge hole, plus engineered mud, directional drilling is much more reliable. For cluster/template drilling, RMR® prevents hole instability which could compromise the development. It also prevents cuttings build-up around the wells. Cementing is much more reliable in a gauge hole, reducing the need for squeezes or ‘top-up’ jobs. This ensures a stable foundation for subsea trees for safe, long-term production.

Watch webinar: Combined Services: How one system can perform three services.

Time and cost comparison

CNR concluded that RMR® was cost effective for a single well, despite extra rig time running the equipment due to crew unfamiliarity with the system. It would produce much greater savings for batch drilling, as well as reduce risks of problems and provide a more stable well.

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

EC-Drill® Dual MPD Technology

Influx Management

Read Case Study:

RMR® Technology

BP, Caspian Sea

Read Case Study: