Case Study:

EC-Drill® Drilling and Completing the Undrillable for Shell

Key Challenges

- Horizontal open holes in an unconsolidated sand reservoir

- Low Pore Pressure Fracture Gradient margin

- Deepwater

- Shallow stacked fan lobe

Benefits

- Improved production with Managed Pressure Gravel Pack

- Simplified Drilling and Completion Operations

- Solids-free production

Challenge

Successfully gravel pack four horizontal open holes in an unconsolidated sand reservoir with low Pore Pressure Fracture Gradient margin.

This field lies in the deepwater Gulf of Mexico in water depths between 7,500 and 10,000 ft (2,290 to 3,050 m). The field geology is characterized by a shallow stacked fan lobe and channel sequence that lies between 1,000 and 3,000 ft below seabed. The sand reservoir is very unconsolidated and highly compressible. The margin between pore pressure and fracture gradient is extremely tight in the target reservoir, between 0.1 to 0.3 ppg (0.83 to 2.5 sg). The tight margins are due to the combination of shallow burial and faulting in the target zone.

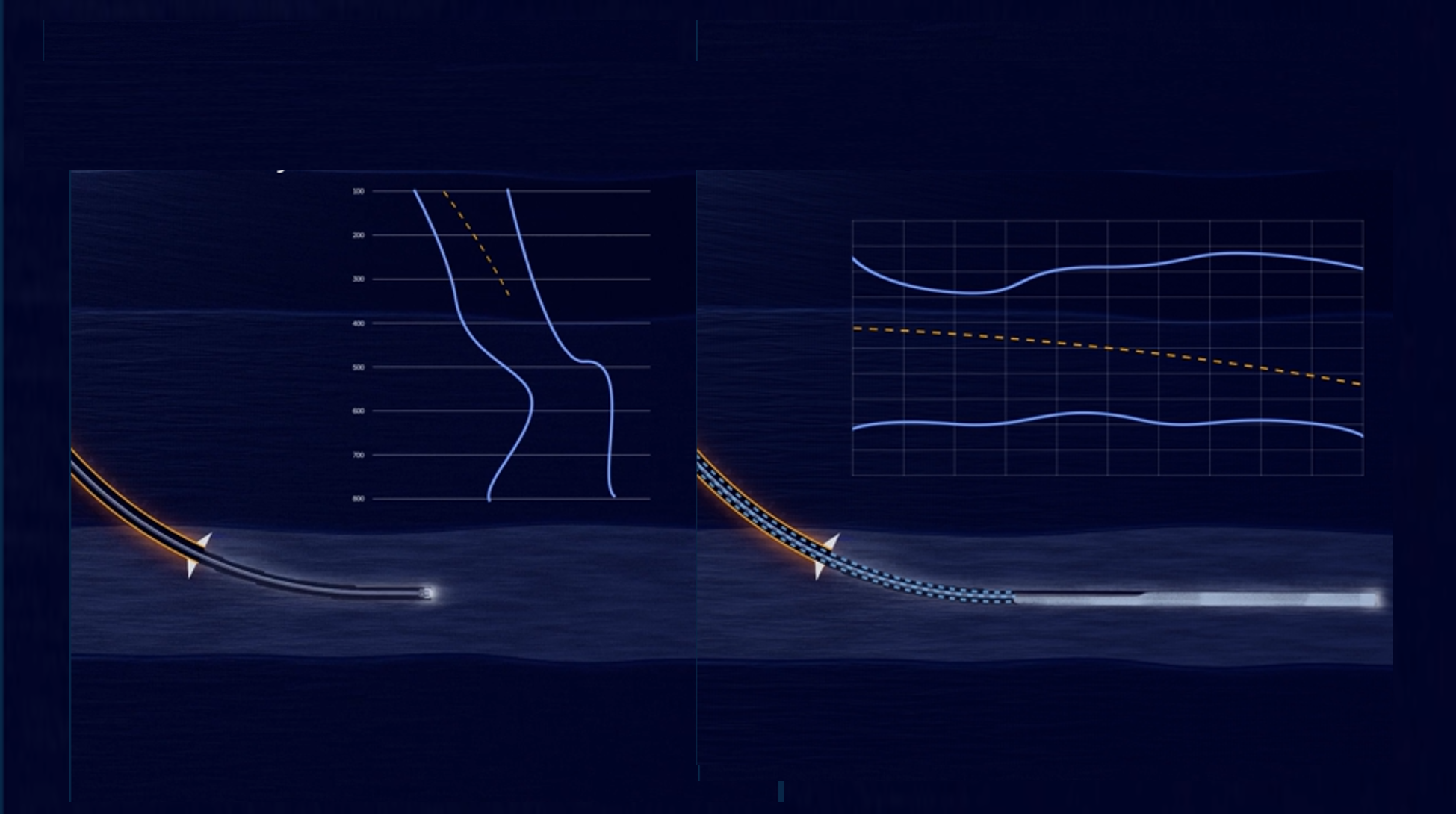

Horizontal Open Hole Gravel Packs were selected for this project because of their predicted high productivity and reliability when executed correctly. The margins between pore pressure and fracture gradient were too small to place these gravel packs conventionally. In order to successfully place the gravel packs in the horizontal targets, the project team needed to manage the pumping treatment such that the downhole pressures would stay between the pore pressure and Possible Loss Line as illustrated in figure 1. Gravel packing the open holes was identified as a critical success factor.

Fig 1: An example plot of Pore Pressure, Possible Loss Line, and Fracture Gradient in the project field.

Watch webinar: World's First Managed Pressure Open Hole Gravel Pack

Solution

A concept selection study was conducted to determine the feasibility of executing gravel packs in these low margin target reservoirs.

The study identified EC-Drill® Controlled Mud Level (CML) MPD technology and light wight proppant as enabling technologies. EC-Drill® CML was the technology that could best handle the gravel packing, drilling, casing, and cementing in the narrow pore pressure and fracture gradient margin. EC-Drill® allows the management of bottom hole pressure by controlling the fluid level in the riser. Gravel packing models showed that EC-Drill® could be used to reduce and hold the pressure at the toe of the well constant. By reducing the fluid level in the riser, EC-Drill® is capable of compensating for the portion of the circulating pressure inside the wash pipe, the service tool, and the casing annulus. The riser fluid level can be continuously monitored and adjusted to compensate for the flowing and hydrostatic pressure between the toe and surface. EC-Drill® enables reducing the static and dynamic pressures during both the alpha and beta waves in gravel, better positioning the pressure profiles inside the narrow margin and reducing the risk of significant losses.

Fig 2: An illustration of pressure profiles during OHGP with EC-Drill®/CML.

The same analysis showed that the flowing friction generated by the slurry in open hole using conventional weight proppant was too high. A special lightweight proppant was developed specifically for the application and used together will EC-Drill® to gravel pack. EC-Drill® could also be used during drilling of the horizontal section to reduce bottom hole pressure and compensate for fluid friction. The pressure compensation enabled the operator to use a WBM to drill the section, instead of an OBM which would have been required if the section were drilled conventionally or with different MPD techniques.

Additional reading: EC-Drill® Enables Gravel Packing Without Inducing Losses

Challenge Solved

The operator successfully executed four horizontal open hole gravel packs in a very challenging reservoir. These were the world’s first Managed Pressure Gravel Pack operations with EC-Drill®.

The successful OHGPs have been confirmed by production results, with solids-free production at expected rates. All four completion operations complied with the operator’s safety process and there was no nonproductive time during pumping. EC-Drill® was the primary enabling technology that enable dynamic control of the pressure in the open hole during placement operations.

EC-Drill® enabled another significant benefit. The fluid density could be increased with EC-Drill® thus enabling the use of water-based fluid for all phases of drilling and completions. This greatly simplified operations by removing the need for a post-pack treatment or breaker. As well as allow WBM to be used during drilling.

Conclusion

- Horizontal Open Hole Gravel Pack in tight pore pressure and fracture gradient window

- EC-Drill® enables reduction and adjustment of downhole pressure during gravel packing improving successful placement of alpha and beta wave

- EC-Drill® allows switching to water-based fluid for entire drilling and completion activities

- EC-Drill® together with lightweight proppant enables operator to successfully gravel pack four challenging horizontal OH

Learn more about EC-Drill® and RMR® here.

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

EC-Drill® Technology

Delivers First MLT TAML Level 5 in Balder Field

Read Case Study:

RMR® Technology

BP, Sakhalin Island

Read Case Study: