Case Study:

EC-Drill® Enables Gravel Packing Without Inducing Losses

Project

In a depleted field re-drill facing collapse and loss risks, EC-Drill® maintained controlled pressure during Alpha and Beta wave gravel packing, enabling full screen-out without losses and ensuring a stable, efficient completion.

Key challenge

The operation faced a narrow margin well in a depleted field with collapse risks, requiring minimized open hole exposure and a full Alpha-Beta wave gravel pack without inducing losses.

Achieve full screen out when gravel packing in narrow margin well

Open hole gravel pack often ends when losses occur – leaving the screens partially packed. This well was a re-drill in a previously produced area, facing collapse issues when drilling and completing. There was a narrow margin between Collapse and Loss Pressure (Pore Pressure below Collapse Pressure). Other wells in the area only managed partial Beta wave packing for going on losses.

Check out this webinar: World's First Managed Pressure Open Hole Gravel Pack

EC-Drill® as the solution

EC-Drill® was used to drill the well to avoid collapse issues and reduce the time the open hole was left exposed from drilling until the screens were run. An innovative approach was planned holding a constant Toe pressure during the Alpha wave portion of the operation, and then hold a near constant Heel pressure while the Beta Wave was packing. This would lead to the pressure at the Toe going below Collapse Pressure after the Toe had been completely packed by the Alpha Wave.

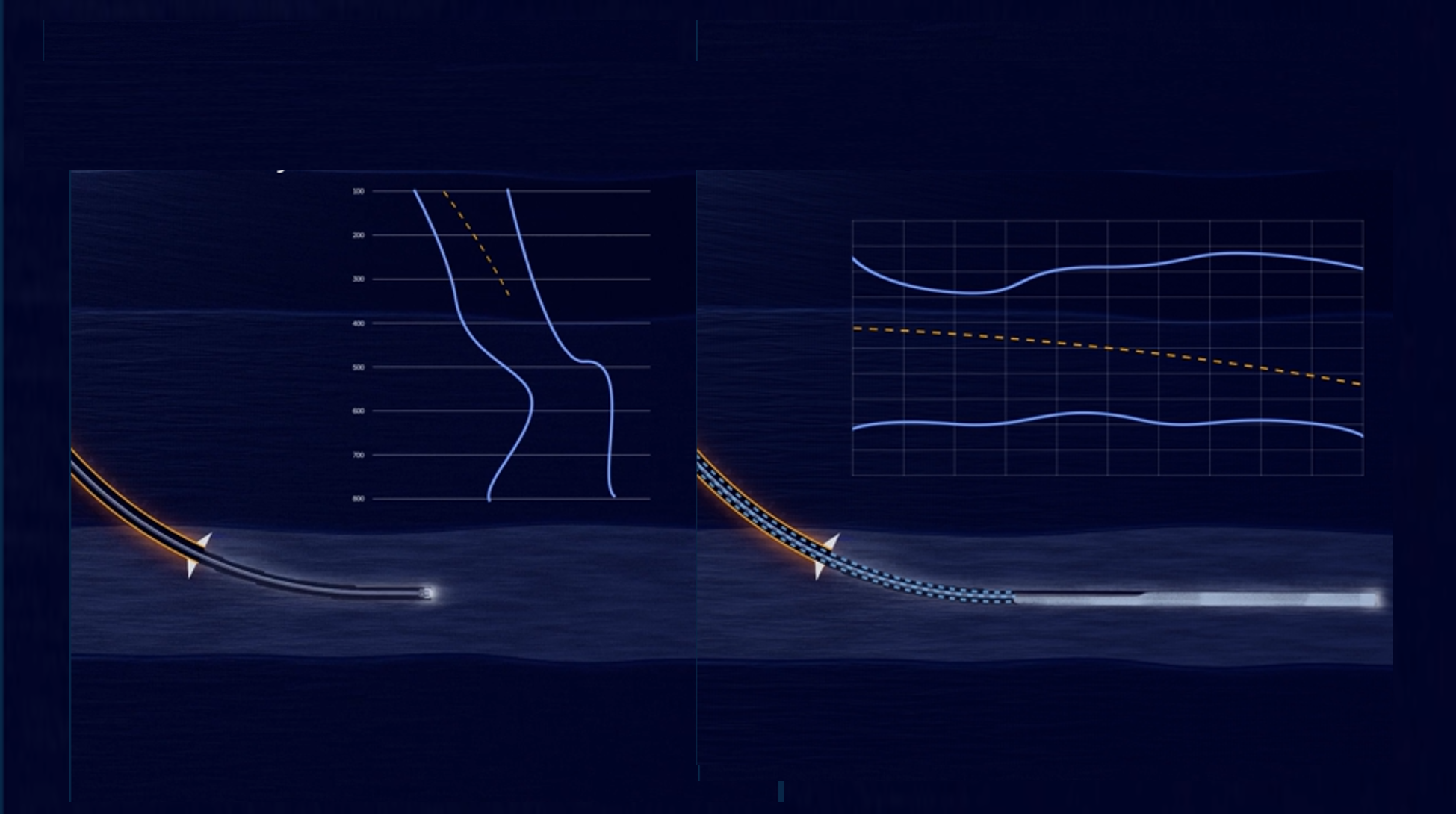

Plot 1: Plan for Gravel Pack with EC-Drill®.

Plot 2: Execution of the planned Managed Pressure Gravel Pack.

Challenge solved

The well was completed with a successful Alpha-Beta wave. The Alpha wave packing was performed using a constant Toe pressure above collapse pressure. During the Beta packing with a near constant Heel pressure, the pressure at the Toe was reduced below collapse pressure in an area of the well already Beta packed.

EC-Drill® is now used consistently for gravel packing.

Learn more about the EC-Drill® here.

Benefits

- Drill in depleted field

- Trip in and out faster and safer reducing time open hole is left exposed

- Managed Pressure Gravel Pack to ensure full screen out

- Increased production

Conclusion

- EC-Drill® enabled drilling in depleted field faced with collapse issues

- EC-Drill® reduced the time the open hole was left exposed by tripping in and out safer and faster

- EC-Drill® achieved a full screen out without going on losses

- EC-Drill improves production when used for completion

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

EC-Drill® Technology

Delivers First MLT TAML Level 5 in Balder Field

Read Case Study:

EC-Drill® Technology

Extending Length of Wells

Read Case Study: