Case Study:

EC-Drill® Instant Kick Detection Demonstrated on Deepwater Well

Project

Enhanced Drilling provided EC-Drill® Managed Pressure Drilling services to a multi-national operator in the Gulf of Mexico. EC-Drill® proved that it is capable of detecting influx far more quickly and reliably than conventional well control methods.

Key challenge

Deepwater exploration in unconfirmed pore pressure regime.EC-Drill® service the answer to kick-detection challenges

A multi-national operator recently used EC-Drill®’s instant kick detection service to complement and enhance conventional kick detection methods during deep-water exploratory drilling in the Gulf of Mexico. It is well known in the industry that deep-water drilling with oil based or synthetic oil-based muds presents distinct challenges to timely detection of influx or losses.

Watch webinar: EC-Drill® - Discover MPD rig integration made easy.

Limitations of conventional kick methods

Although effective, conventional methods of kick detection have limitations and can allow influxes into the wellbore at a rate and volume that make well control more difficult. Normal drilling in deepwater environments presents its own set of challenges, including the potential for an influx while making a connection. Statistically, 70 per cent of kicks occur during connections (Fraser et. al., 2014)*.

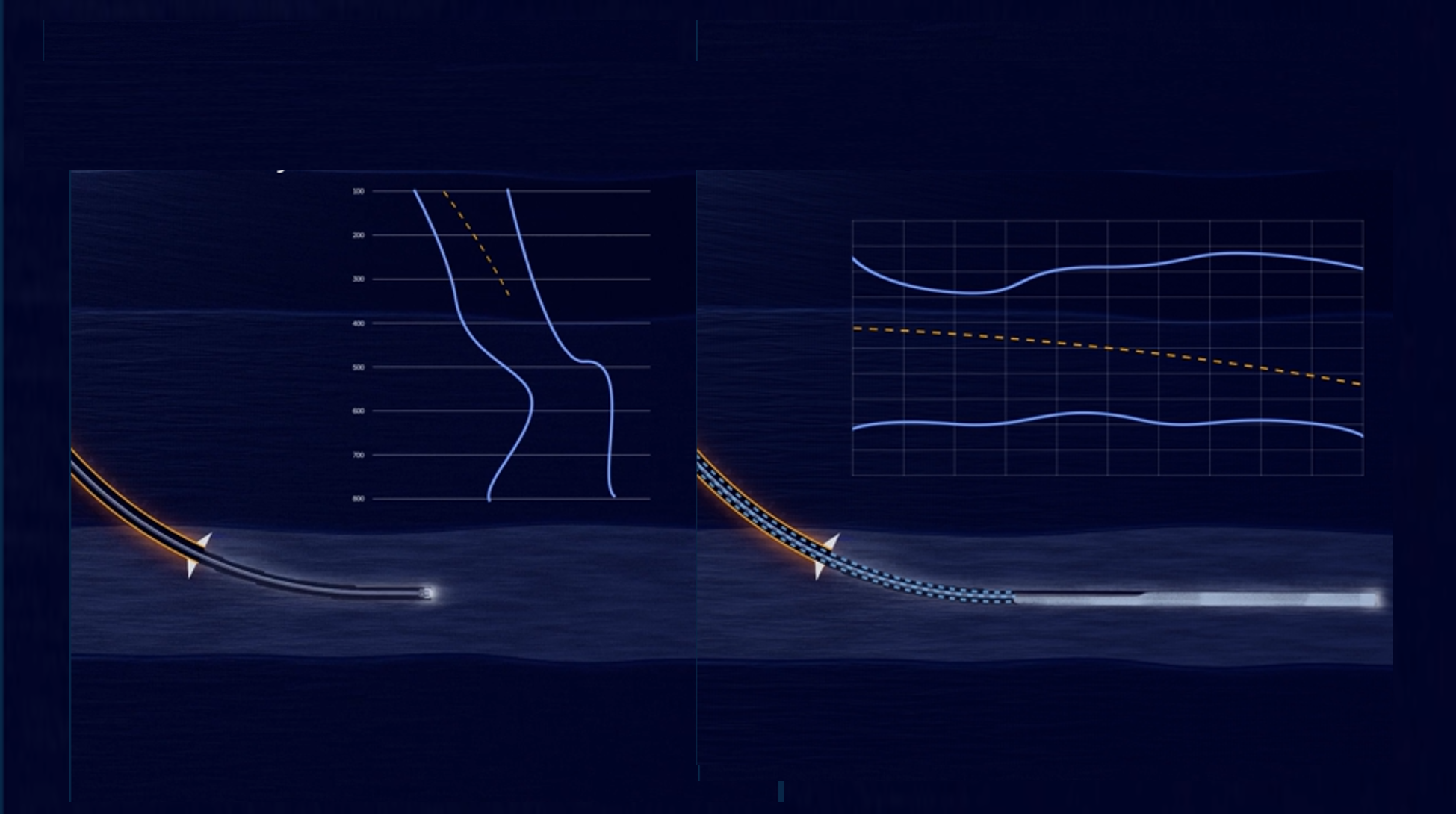

EC-Drill® detects influx 40 seconds faster than flow-out measurements

To improve kick detection response times, the operator used EC-Drill®’s optional ‘instant kick detection’ service. During kick drills and while drilling, EC-Drill® demonstrated that it is capable of detecting kicks with both its pump performance and riser pressure sensors. These sensors are the first indicators and are capable of detecting flow anomalies at least 40 -60 seconds faster than conventional flow-out methods and a full 20 seconds earlier than mud pit volume totalizer methods (see Figure 1, overleaf). The drill crews using the system concluded that the EC-Drill® method of making the riser above the pump a new and ‘first in-line’ trip tank is more accurate and more reliable than conventional kick detection methods.

Figure 1 shows how an influx is detected immediately by the riser pressure sensor (blue) followed by the EC-Drill® pump speed (green) 10 seconds later. After 48 seconds the flow increase is detected by the flow measurements from the coriolis.

Additional reading: CCS, SBP, CML - A Comparison Guide

Instant kick detection - reduce risk, enhance safety

The implications of being able to detect kicks and losses far ahead of conventional methods are significant, from overall safety and reduced risk to equipment and personnel, to drastically improved ability of crews to manage and control an influx that has been minimised by early detection and early response. The operator gains a ‘step change’ in kick detection with this technology

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

EC-Drill® Technology

Dual Gradient in Gulf of Mexico Deepwater

Read Case Study:

EC-Drill® Technology

Delivers First MLT TAML Level 5 in Balder Field

Read Case Study: