Case Study:

RMR® – Ormen Lange, North Sea

Key Challenges

- Deepest RMR® North Sea - Riserless Mud Recovery

- Shallow hazard mitigation

- Harsh weather conditions

- Tophole instability

- "Pump & dump"

Benefits

- Cost savings

- Tophole stability

- Riserless drilling with mud returns

- Zero discharge

Challenge

A major operator in the North Sea planning to drill a subsea well was facing issues in the design of the extended reach casing program, as the step out from the template to the target required an additional casing string to maintain the 9-5/8” at a deployable length at 70° inclination sail angle.

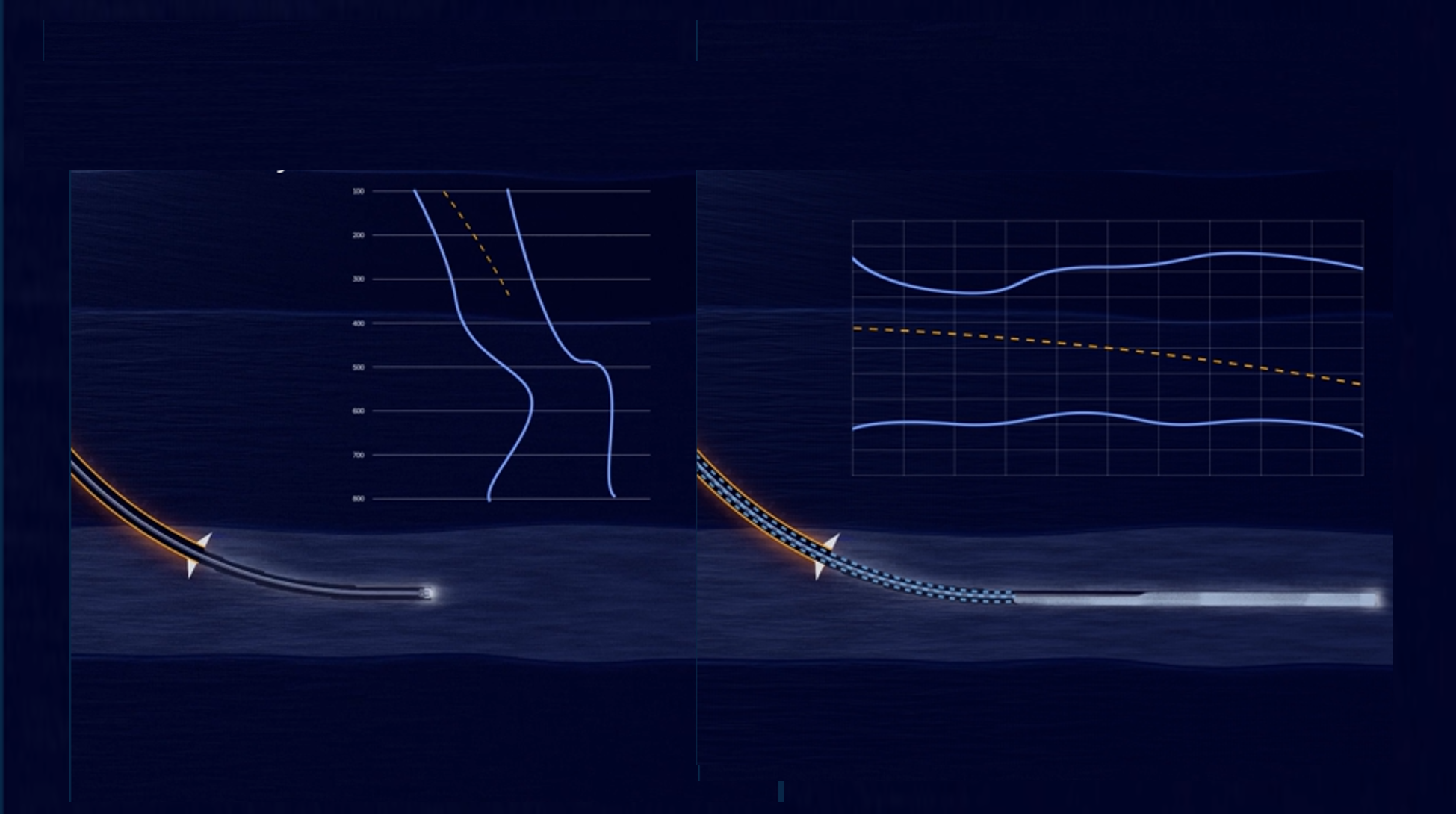

Using the field’s datum well design, the 20” shoe setting depth constrained by a shallow hazard anomaly (drilled pre-BOP with seawater and sweeps followed by pump and discharge prior to TD) would have resulted in a 2,800m long 12 ¼” section at 70° inclination angle throughout the section. Based on drag modelling at the fields historical friction factors it would not have been feasible to deploy the 9 5/8” liner at this length and inclination.

Using the field’s datum well design, the 20” shoe setting depth constrained by a shallow hazard anomaly (drilled pre-BOP with seawater and sweeps followed by pump and discharge prior to TD) would have resulted in a 2,800m long 12 ¼” section at 70° inclination angle throughout the section. Based on drag modelling at the fields historical friction factors it would not have been feasible to deploy the 9 5/8” liner at this length and inclination.

/RMR/North%20Sea%2c%20Ormen%20Lange_1.png?width=807&height=629&name=North%20Sea%2c%20Ormen%20Lange_1.png)

Solution

Deepest 20” casing and longest 26” section on the Ormen Lange Field Using an RMR®system and the benefit of dual gradient drilling technology, the 26” section was drilled with a weighted mud. The higher mud weight allowed the 20” casing to be set 400 m deeper allowing a higher mud weight to be employed in the subsequent hole section and enable setting of the 13 5/8” sufficiently deep to maintain the 9 5/8” liner at a deployable length.

Pump and discharge was considered. However, given the volume of mud required for a 26” section of this length and the harsh weather conditions posed by the deep water fields location offshore Norway, pump and discharge was dismissed as an option.

/RMR/North%20Sea%2c%20Ormen%20Lange_2.png?width=797&height=619&name=North%20Sea%2c%20Ormen%20Lange_2.png)

Historically, 17-1/2” hole has been drilled using RMR®offshore Norway in 460 m water depth taking returns via a 6” id hose. The increased water depth and increased hole size dictated that an 8-5/8” return casing be used to reduce the parasitic losses to allow a flow rate sufficient to clean the 26” hole while building to 33° inclination.

Using Dual Gradient Drilling a heavier drilling fluid can be used, increasing the Equivalent Mud Weight (EMW). The increased EMW and associated drilling pressures creates greater overbalance to the pore pressure even as the section depth is extended. This enables the 20” casing to be installed 400m deeper than conventionally.

Additional reading: Case study: RMR® - the simple solution to top-hole instability problems.

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

RMR® Technology

BP, Sakhalin Island

Read Case Study:

EC-Drill® and RMR® Technology

Providing Large Savings for major Operator on NCS

Read Case Study: