Case Study:

MPC® BP, Caspian Sea

Key Challenges

- Narrow pressure windows

- Cement slurry loss

- Notorious sands

- Shallow water and gas flow

Benefits

- Cost, safety and efficiency enhancing

- Enables safe cementing in narrow fracture/pore pressure windows and while drilling through unstable formations

- Enables use of conventional cement (not foam or nitrified)

The cementing of top-hole sections in narrow pressure windows has traditionally been highly problematic. Learn how MPC® enables BP to cement 22”surface casing and isolate notorious sands.

Challenge

Cementing top-hole sections in a narrow pressure window. The cementing of top-hole sections in narrow pressure windows has traditionally been highly problematic. This has been due to cement slurry loss, plus shallow water and gas flow.

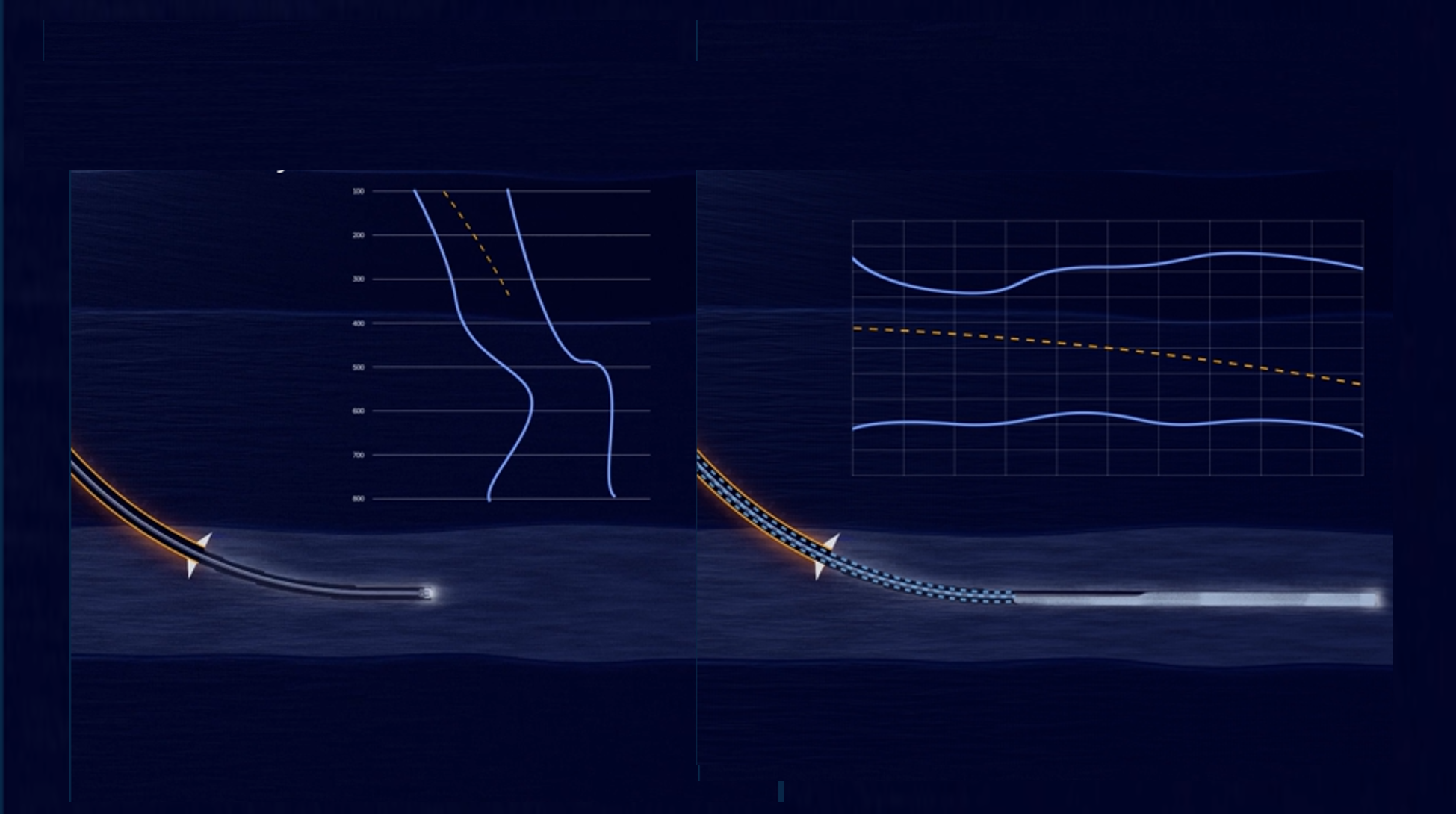

Safety and environmental best practices dictate drilling and cementing the top-hole wellbore with full control over the returns from fixed offshore platforms. This is because there is no possibility to drive off if a continuous flow of gas into the wellbore should occur. In the case of this particular BP well in the Caspian, highpressure-fluid-bearing (water with dissolved gas) sand strata below the 28” liner shoe required drilling with a minimum 1.44 S.G. (12 ppg) mud (Fig. 1). With a fracture gradient of 1.48 S.G. (12.34 ppg) at the last casing shoe, it was literally impossible to cement the 22” casing with properly weighted cement slurry with returns to the surface during cement slurry placement.

MPC® enabled the challenge to be over come. An environmental 36” riser had been connected to the Low Pressure Housing (LPH) with a diverter on the sur face to allow for safe drilling and cement ing operations. 1.65 S.G. (13.76 ppg) cement slurry was selected but the 28” shoe still wouldn’t withstand the wellbore pressure should the top of the cement slurry reach just a few meters above it. Fig. 2 shows how the wellbore pressure exceeds the fracture pressure of the for mation when cement slurry flows toward mudline, above the weak zone. This will lead to losses of slurry to the formation resulting in hydrostatic pressure reduction. This eventually could cause the high pressure-fluid-bearing sand to flow.

/MPC/BP%2c%20Caspian%20Sea_1.png?width=881&height=533&name=BP%2c%20Caspian%20Sea_1.png)

Fig. 1: Wellbore status before running the 22” casing.

Another problem with conventional cementing is hydrostatic pressure loss inside the annulus as a result of cement slurry volume reduction and gelation during setting time. The wellbore becomes underbalanced and the fluid starts flowing to the well. This can damage the cement, wellbore and even the entire template.

Case study: Learn how MPC® was vital in enabling BP to achieve effective top-hole cementing.

Solution

With Managed Pressure Cementing (MPC®), it is possible to reduce the pressure when the weak zone is exposed to higher hydrostatic pressure during circulation. This is done by reducing the wellbore pressure as the cement slurry flows up the annulus. MPC on BP’s well in the Caspian was performed by establishing a closed loop circulation system for placement of cement slurry; the annulus of the wellbore was accessed by an Enhanced Drilling subsea pump through the Low Pressure Wellhead’s (LPWH) flow-by holes.

This facilitated an excellent level of control over the flow and wellbore pressure, both automatically and manually. Enhanced Drilling subsea disk pumps have a track record of success on more than 500 Riserless Mud Recovery (RMR®) jobs around the world to date. This proven key component of the MPC® system enables operators to get returns to the rig while monitoring and controlling wellbore pressure and return flow during tophole drilling operations.

Crucial parameters such as return flow rate and power consumption by the motors are used to quickly identify any loss of cir culation to or gain from the formation. This functionality was crucial for the successful placement of cement slurry against notorious high pressure, unconsolidated sands.

/MPC/BP%2c%20Caspian%20Sea_2.png?width=970&height=553&name=BP%2c%20Caspian%20Sea_2.png)

Fig. 2: Wellbore pressure would exceed fracture pressure as the cement slurry flows above the weak zone.

Challenge Solved

After the cement was pumped, the annulus was shut in by closing two valves installed on the wellhead. Filtrate loss to the formation - which would have resulted in significant hydrostatic pressure loss of cement slurry was prevented, and therefore so was gas-flow to the wellbore.

Due to pressure equilibrium reached between wellbore and formation, formation fluid would not breach into the contained cement.

Learn more about the MPC® technology here.

Conclusion

- Notorious high pressure, unconsolidated water/gas bearing sand strata were success fully isolated with high-performance cement.

- No water/gas flow after cementing. Well did not become underbalanced during cement setting

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

EC-Drill® Technology

Troll field, North Sea

Read Case Study:

MPC® Technology

BP, Caspian Sea: Cement 22" Surface Casing and isolate notorious sands

Read Case Study: