Case Study:

RMR® – US Gulf of Mexico

Successful use of RMR® in 2,034ft (620m) water depth

How to drill a surface hole in an area known for geo-hazards

Statoil planned to drill an exploration well in the Mississippi Canyon block in the Gulf of Mexico. The MC540 well, Krakatoa, had a target depth of 25,000ft (7620m) TVD SS. The 22” surface casing needed to be set just above a seismic anomaly at 5,583ft (1700m) TVD SS. The area is known for shallow geo-hazards.

Some problems anticipated by Statoil were:

- Deep water: 2,034ft (620m)

- Unstable turbidite formations

- Shallow Water Flows (pressured sands)

- Shallow Gas sands (overpressured)

- Reactive clays (‘gumbo’)

The problem for the drilling team was how to minimise these risks. The main priority was to use weighted mud to prevent gas or water flows. Ideally this mud would be inhibited and heavy enough to prevent shallow flows. Fluid Loss Control would also be useful.

Additional reading: Case study: RMR® - Ormen Lange, North Sea

Alternative 1 – ‘Pump & Dump’

The standard Gulf-of-Mexico way to prevent influxes while drilling tophole is to use weighted mud discharged at seabed. Simple weighted mud, 16.0ppg (1.9SG), is mixed onshore and shipped to the rig. It is diluted to the required weight by mixing it with seawater just before pumping down the drill string. The advantage of Pump & Dump (PAD) is that the hole is kept full of weighted mud when drilling, tripping and running casing. Plus, the method works as well at 10,000ft as at 1,000ft.

However, it also has significant disadvantages:

- Low specification mud (high inhibition or fluid loss control is too expensive)

- Cost of the large volume of mud, plus logistics to mix and transport to rig

- Environmental effect of mud discharge

- Operations can be delayed due to logistics problems or weather.

These problems are not as significant in the USA where a whole industry has grown up to service this method. In other areas of the world they are much more serious because of the lack of bulk mud supply infrastructure and stricter environmental controls.

Alternative 2 - RMR®

Statoil were aware of the RMR® system provided by AGR. They had used RMR on 26 exploration, appraisal and development wells. The concept is simple; the mud and cuttings are pumped from the wellhead back to the rig flowline, by a subsea pump, through a flexible mud return line.

The advantages of RMR® over PAD are:

- Practical to use fully engineered mud with inhibition and fluid loss control

- Total mud volume is monitored at all times to check for gains

- RMR® pump is an accurate flowmeter

- <10% mud volume needed

- Reduced discharge to sea

Specification of RMR® equipment

A standard RMR® pump ‘stage’ is made up of a 300kW electric motor and a ‘Disc-Flo’ pump housing. A single stage pump is adequate down to 500ft (180m) water depth. For Krakatoa, the deepest ‘over-the-side’ RMR® job to date, 4 stages (in series) were needed. Two doubleended 600kW motors were built into a Pump Module. The other equipment was standard.

Preparation for RMR® operations

Statoil decided to jet the 36” conductor in place before drilling the next section and cementing a 28” casing at 3,475ft (1060m) TVD SS. This section was drilled with seawater and sweeps with returns to the seabed. RMR® equipment was installed off-line so no additional rig time was needed. The suction module was run on drillpipe rather than pod line as there were no guidelines to the wellhead.

Metal parts of the cementing equipment were lost inside the 28” casing and had to be milled up using mud with returns to surface through the RMR® system. Without RMR®, at least 60,000bbls (9,550m3) would have been used before drilling started./RMR/US%2c%20Gulf%20of%20Mexico.png?width=958&height=605&name=US%2c%20Gulf%20of%20Mexico.png)

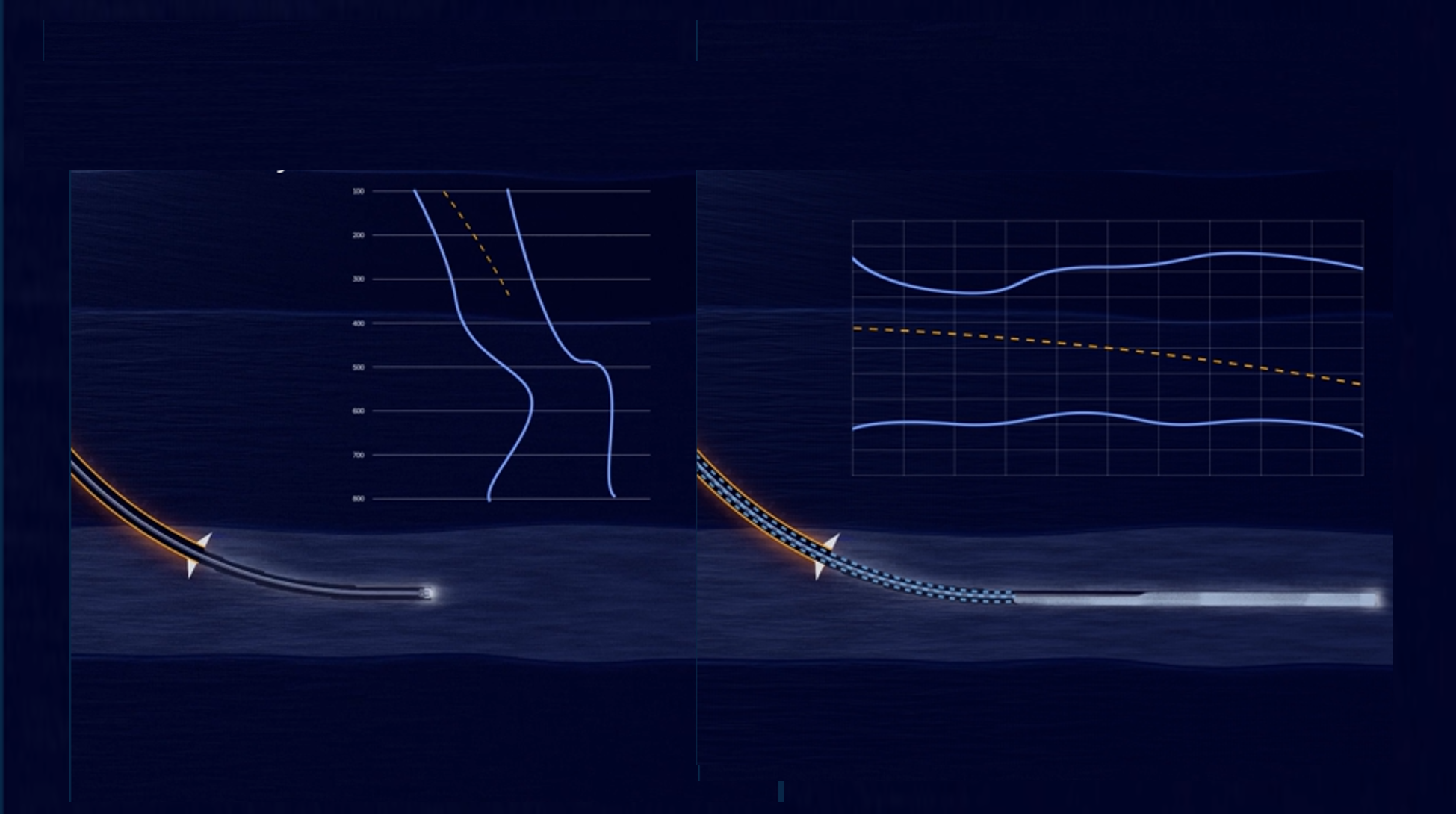

Graph: Krakatoa PP. FG, OBG and SFG (Planned Vs Actual). NOTE: All numbers are ‘downhole values’ = PP, ESD and FG.

RMR® Operations drilling 26” hole

Statoil started drilling with 11.0ppg (1.3sg) inhibited water-based mud, then increased the weight to 13.4ppg (1.6sg) by section TD. Drilling started with a flow rate of ~900gpm (3400lpm) at a maximum instantaneous drill rate of 90fph (27m/hr). The RMR® pump was adjusted to match the rig pump flow rate and to return all mud and cuttings to the rig.

The depth of the pore pressure increase was underestimated so there was a shallow water flow into the well. This was countered by increasing the mud weight. The water influx triggered the clay cuttings to stick together to form a large mass of ‘gumbo’.

This was cleared by stopping the RMR® pump and continuing with the rig pumps to force it out the Suction Module into the sea. The gumbo blocked the suction of the RMR® line which then collapsed. However the ROV unlatched the Suction line and another was installed without having to pull the Pump Module or Suction Module.

A shallow gas kick was taken in the section as the mud weight was too low. This was identified within a minute (<0.5bbl [0.1m3] influx) by an increase of the RMR® pump rate. The mud weight was increased to 14.3ppg (1.7sg) at section TD.

Read more about the RMR® technology here.

Conclusions

- RMR® and inhibited mud drilled 1,852ft (564m) of 26” hole in 168-hours;

- RMR® handled 14.3ppg (1.7SG) mud in 2,034ft (620m) water depth;

- 22” casing cemented successfully at 3,140ft (960m) below mudline (best in class for area);

- Mud discharged was <10% of PAD.

RMR® can improve overall well construction. With engineered mud, it enhances drilling operations and provides excellent wellbore stability. Now proven for >2,000ft (620m) WD.”

OTC 20939 T. Grønås, T. Martin, T. Tveit Statoil et al.

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

EC-Drill® Technology

Delivers First MLT TAML Level 5 in Balder Field

Read Case Study: