Download Case Study:

RMR® – INPEX, Browse Basin

Key Challenges

- Tophole Stability

- Deep surface casing

- Riserless drilling with mud returns

- Reduced risk in drilling

- Simple solution to major problem

The Grebe sand in Australia’s Browse Basin has caused drillers major problems in the past due to the tendency of unconsolidated soft sands falling into the wellbore. This slumping caused pack-offs and stuck pipe, which can prevent casing being run to depth. Learn how this problem was solved using RMR® services.

The problem: soft Grebe sand

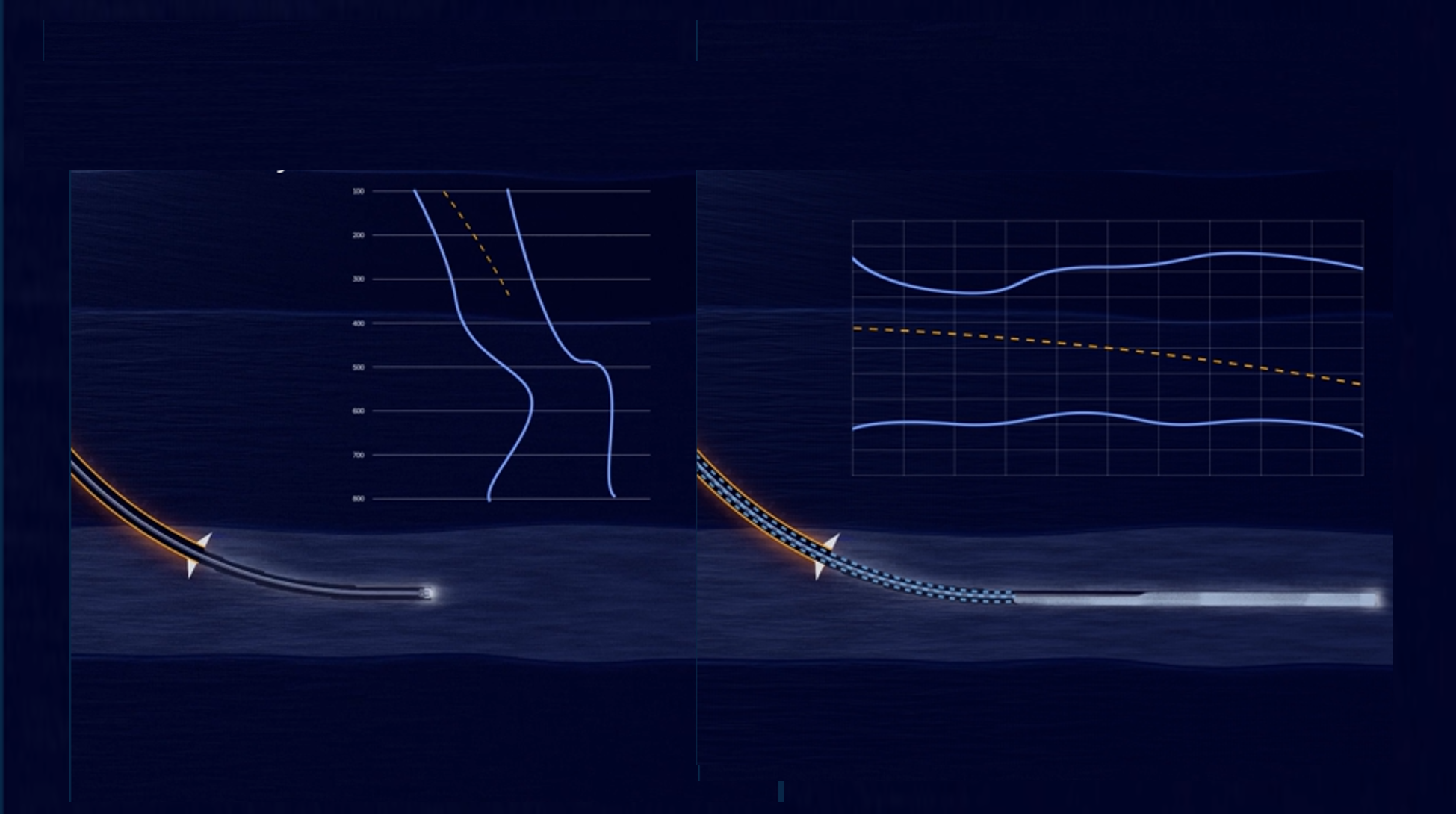

The Grebe sand in Australia’s Browse Basin has caused drillers major problems in the past. The problem is not shallow gas or shallow water flow but that, when the sands are drilled with seawater/ sweeps, the unconsolidated soft sands tend to fall into the wellbore. This slumping caused pack-offs and stuck pipe. It can prevent casing being run to depth. The conventional solution is to set 20” surface casing above the Grebe and run the BOP on the riser. The next section is drilled with mud with returns to the surface before setting intermediate 13-3/8” casing below the Grebe. Because there are weak zones below the Grebe, it can be difficult to drill with mud returns from seabed to the rig.

“INPEX drilled wells in the Browse Basin with seawater/sweeps in the top hole. Slumping sands caused pipe to stick on many occasions and caused two re-spuds. The area is well known as the most difficult top hole in Australia.

Vince Tilley, Drilling Superintendent INPEX

The solution:

the RMR® system from Enhanced Drilling INPEX decided on an aggressive casing design with 13-3/8” surface casing at 2,500m (8,200ft=. TO achieve this, a subsea pump was needed so that engineered mud was used and re-circulated back to the rig before the rig riser was run. With Enhanced Drilling’s RMR®, the well objectives were achieved without the extra time and cost of 20” casing. Having RMR® also meant better control of the ECD because the RMR® pump lifted the mud and cuttings from the seabed.

Watch webinar: RMR® - Riserless Mud Recovery System

Installation of the RMR® system

The Songa Venus rig was moored at the Dinichthys North-1 location in approximately 265m (870ft) of water. A 36” hole was drilled to 339m (1,112ft) with seawater/sweeps and the 30” conductor cemented. At the same time, the RMR® Subsea Pump Module (SPM) was installed on the seabed over the side of the rig (outside of the rig-critical path). The RMR® Suction Module (SMO) was run on a Pod Line and landed on the Low Pressure Wellhead Housing while preparing to pick up the 17-1/2”BHA.

RMR® surface equipment on Songa Venus

Unfortunately, the ROV got tangled in the guide wire while being run through the splash zone. The ROV had to be fished out for repair. It was decided to change plans, and instead drill down to the top Grebe with seawater/sweeps with returns to the mud line. The ROV is needed to run the suction line and control line from the SPM and attach them to the PMO. Problems with the ROV arm and strong currents delayed this operation.

“The RMR® system was successfully used by INPEX and the slumping sands have been very stable. The top hole has become ‘routine’ drilling. The technology is very robust and the pump was run for many hours of continuous drilling with a huge volume of cuttings, with no ill effects on the pump or ancillary equipment.

Vince Tilley, Drilling Superintendent INPEX

Additional reading: Case study: RMR® - Ormen Lange, North Sea

Drilling Surface hole

After installing the RMR®, the 17-1/2” hole was displaced to unweighted bentonite polymer mud with additional Fluid Loss Control (kept at approximately 8ml). The Grebe sand was frilled from 1,000m (3,281ft) to 1,525m (5,000ft) controlling the drill rate to a maximum of 60m/hr (200fph) to avoid overloading the annulus with cuttings. There were no mud losses in the Grebe and the hole condition was good, with no pack-off or string sticking. The pump rate was approximately 3,800lpm (1,000gpm) with 175 mesh shaker screens. The full use of Solids Control Equipment and dumping kept the mud weight at 1.08SG (9ppg).

Mud losses started below the Grebe, associated with weak zones below hard stringers. These losses were solved by picking up and stopping circulation for five minutes without cleaning the hole. The drill cuttings helped the mud to seal the loss zones and build up a filter cake. Circulation back to the rig, via the RMR® unit, was always regained.

A planned bit-trip was made at 2,116m (6,942ft) to change to a packed 16”BHA with full FEWD tools. There was only one section of 30kips overpull at 1,930m (6,332ft) which was easily reamed out. At section TD 2,500m (8,202ft), the lower section of the hole was displaced to KCI mud to control reactive shale. There was only 20kips over-pull from TD to 2,300m (7,546ft) but, otherwise, hole condition was good.

/RMR/Browse%20Basin.png?width=661&height=509&name=Browse%20Basin.png)

Descent: Running SMO on Pod Line.

Four-day crane delay - but hole remains stable

Unfortunately there were serious problems with both the rig cranes which resulted in over 4 days of downtime before the casing could be run. The only problem was that the mud properties suffered with bacterial decay. A trip was required to displace the hole to new KCl mud. However, the hole remained stable and in good condition. The SMO was retrieved with a Pod Line winch (again off the critical path). The casing was run to the planned depth, landed and cemented without problems

Conclusions

Being able to use an engineered mud with Fluid Loss Control prevents slumping of massive, unconsolidated sands. The RMR® system allows engineered mud to be used in a closed system with returns to the rig. This ensures minimal downtime and a stable top hole, even with a four-day delay in running casing. The 20” casing string can be safely left out when the RMR® system is used to minimise the risks of top-hole drilling and maintain a stable surface hole. The risks of top hole drilling and maintain a stable surface hole.

“The interface of the RMR® system with the ROV and the installation of the pump, flow line and electrical lead, has been challenging in this area with its strong currents and poor visibility. However, with patience and careful planning, these problems have been overcome. I would not hesitate to recommend this system to anyone drilling in this area or in similar environments.”

Vince Tilley, Drilling Superintendent INPEX

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

EC-Drill® Technology

Benefits Displayed on Shah Deniz

Read Case Study:

RMR® Technology

BP, Caspian Sea

Read Case Study: