Case Study:

RMR® – BP, Caspian Sea

RMR® solves BP’s West Azeri hole instability problems

Project

Enhanced Drilling provided RMR® services to BP in the Caspian Sea in 2004.

Key words

- Tophole Stability

- Loss of Template

- Tectonically Active area

- Reduced risk in drilling

- Improved safety

Summary

Problems with shallow formations forced BP to abandon its West Azeri template in the Caspian Sea. To prevent similar problems, BP now jets the 30” conductor and drills the surface hole using Enhanced Drilling’s Riserless Mud Recovery (RMR®) system. This is now standard operating procedure for BP’s wells in the area.

/RMR/BP%20Caspian%20Sea_1.png?width=722&height=508&name=BP%20Caspian%20Sea_1.png)

RMR® subsea pump module

The West Azeri Field template

BP was developing the West Azeri field in 2003 with a semi-submersible and a subsea template set in a water depth of 120m (394ft). The first well was drilled and completed successfully. Then nine 30” conductors were cemented successfully at approximately 295m. When drilling out the 30” shoe on the sixth well, however, some movement of the 30” shoe was noted. In the next well there was high angle at the shoe and drilling was suspended. The wells were surveyed and the results showed that there was deflection in the wells from 270m (886ft) – 310m (1,017ft) (30” shoe).

THERE WAS UP TO:

- 1.5m (5ft) horizontal displacement

- 24o /30m doglegs

The template was abandoned.

Failure Mechanisms

A MULTI-DISCIPLINARY BP TEAM INVESTIGATED THE PROBLEM AND IDENTIFIED THE FAILURE CAUSES:

- Low soil strength; formation flows into the hole destabilising local area

- Pore fluid salinity is 250gm/kg (Caspian Sea water = 6 gm/kg)

- Shallow overpressure

Watch webinar: Combined Services: How one system can perform three services

The solution to the problem

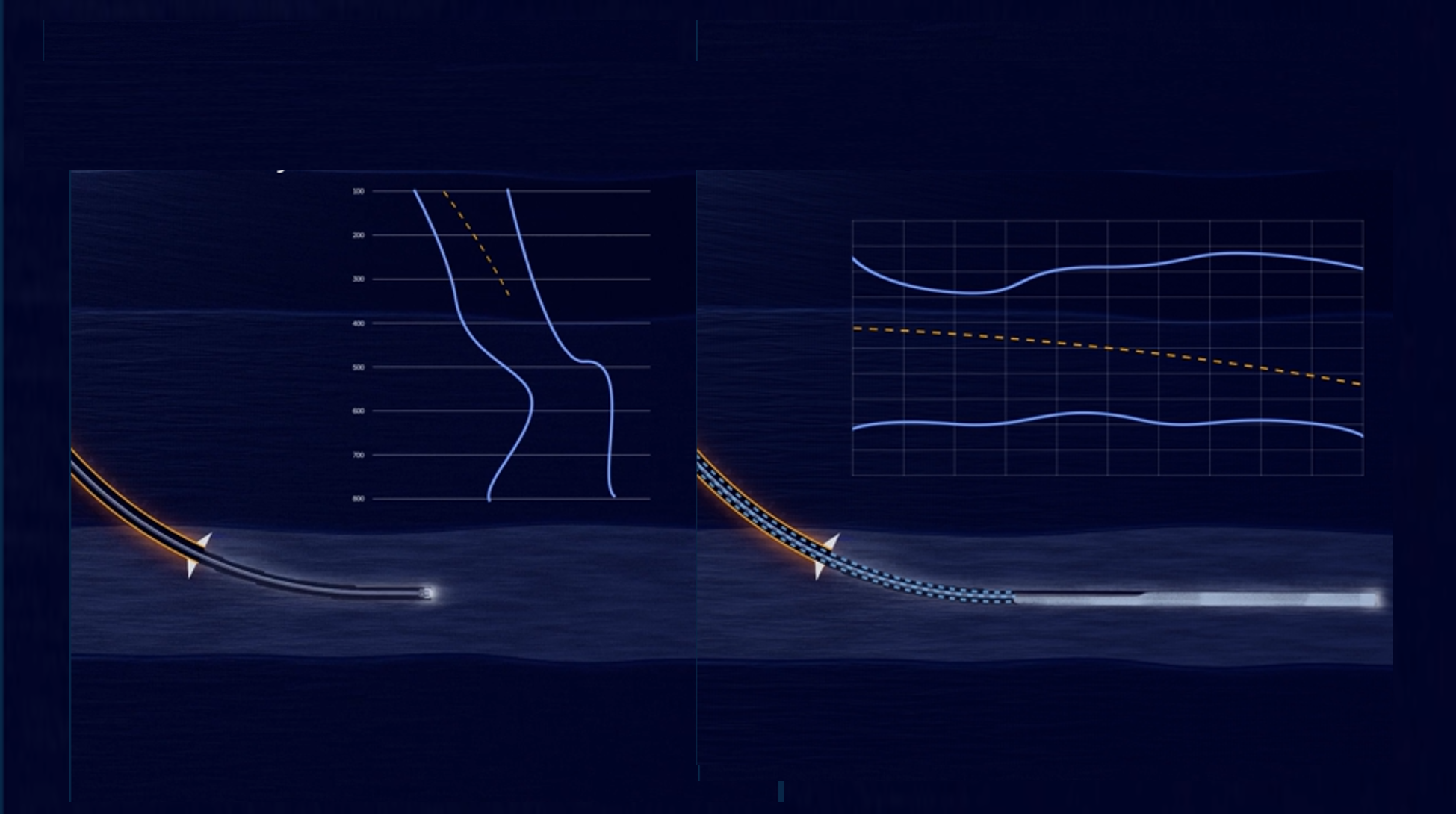

The 30” conductor was jetted into place so the shallow formations were not exposed to drilling fluid or cement and there was no chance of the hole walls collapsing. The RMR® system was then installed as an inhibitive, weighted mud system that could be used to drill the surface hole (24”) with mud returns to the rig. Use of sacrificial mud (‘Pump & Dump’) was not an option, due to the cost of the mud and logistics constraints.

/RMR/BP%20Caspian%20Sea_2.png?width=700&height=575&name=BP%20Caspian%20Sea_2.png)

RMR® suction module.

Advantages of RMR® system

The Enhanced Drilling-designed-and-operated Cutting Transport System (CTS) is a subsea pump that moves drill waste away from wellheads. The system was further developed into RMR®, enabling the transportation of mud and cuttings from surface hole (or holes) back to the rig. The system is used before the BOP and rig marine riser are installed. With this ‘closed loop’ system, high-specification mud can be used as it is returned to the rig with no discharge.

FOR THE WEST AZERI WELLS, THE ADVANTAGES OF RMR® WERE THAT:

- High salinity mud was used to balance the high salinity of the pore fluids

- Weighted mud to balance Pore Pressure

- Inhibited mud to stop clay reaction

- Fluid Loss control to minimise volume of fluid reacting with formation

Additional reading: Case study: RMR® - Ormen Lange, North Sea

RMR® Equipment

Mud is collected at the seabed by the Suction Module (SMO) which is clamped to the Low Pressure wellhead. The suction line, installed by ROV, takes mud to the Pump Module (PMO) on the seabed. The Discflo pump then transports the cuttings up the 6” Mud Returns Line back to the rig shakers and to the mud pits for recirculation.

The SMO is deployed through the Moon Pool using drill pipe or guidelines. The PMO is lowered over the side of the rig on an umbilical with a dedicated winch, making up sections of Mud Return Line as it is lowered.

The subsea operations are observed with RMR® cameras with the ROV as back-up. There is also a pressure gauge to monitor the mud level in the SMO. Surface equipment consists of a control cabin and an electrical generator for the pump if there is not enough rig power.

During RMR® operations, the driller makes up the pipe and drills normally. The RMR® operators start, stop and adjust the RMR® pump so that no mud overflows the SMO. The pump is highly responsive, meaning the level can be controlled within a few centimetres. There is a very distinct interface between the mud and seawater in the SMO.

“A weighted, high performance water based mud in a circulation system was required to successfully drill the West Azeri shallow soils. RMR® technology was the only viable option to achieve this.” Edvin Kvalvaag, BP West Azeri Project Manager

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

RMR® Technology

BP, Egypt

Read Case Study: