Case Study:

MPC® BP, Caspian Sea

Key Challenges

- Unconsolidated sands

- High-pressure shallow water

- Low fracture gradients

- Narrow drilling pressure window

Benefits

- Cost, safety and efficiency enhancing

- Enables safe cementing innarrow fracture/pore pressure windows

- Enables use of conventional cement (not foam or nitrified)

Presence of high-pressure shallow water and gas in the Caspian region, notorious for its unconsolidated formations, had previously imposed a lot of costs on BP. Learn how MPC® was vital in enabling BP to achieve effective top-hole cementing.

Challenge

Presence of high-pressure shallow water and gas in the Caspian region, notorious for its unconsolidated formations, had previously imposed a lot of costs on BP.

BP ran 22” surface casing string to 1,100mTVD (3,609ft) off the Istiglal semi submersible rig in the Caspian. The rig was in a water depth of 163m (535ft). The casing string was successfully cemented and unconsolidated, high-pressure sand was effectively isolated by using Enhanced Drilling’s Managed Pressure Cementing (MPC®) system.

Additional reading: Learn how MPC® enables BP to cement 22”surface casing and isolate notorious sands.

Low fracture gradients

It was necessary to use 1.70S.G. (14.0ppg) drilling mud for drilling 26” top-hole sections through shallow high-pressure sand stratum. However, circulation of cement slurry heavier than 1.75S.G. (14.6ppg) was not possible due to low fracture gradients in the shallow, unconsolidated formations; high slurry densities would cause slurry losses to the formation. This would lead to a loss in hydrostatic pressure against the high-pressure zone and, eventually, a flow from the highpressure sand. Furthermore, a certain hierarchy between the mud, spacer and cement slurry was needed to ensure efficient mud removal and displacement. In similar cases in the region, BP had experienced a few failed attempts to control gas flow after cementing. Implementation of sophisticated gas-control techniques, such as nitrified cement slurry, had not proved very successful. MPC® was a vital tool in enabling BP to achieve its top-hole cement objectives. No gas flow either during or after cementing was encountered.

MPC® from Enhanced Drilling

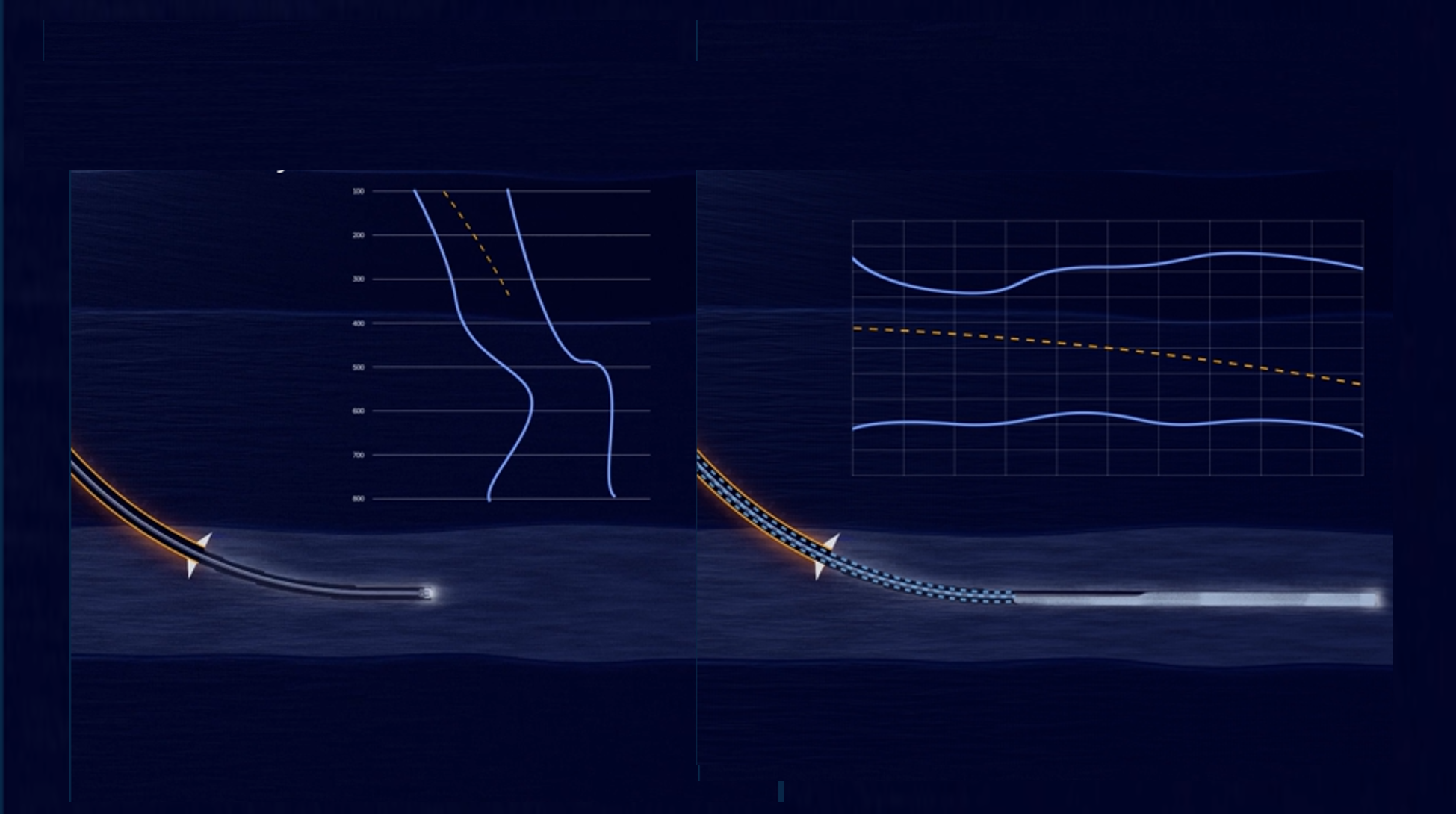

MPC® enables the management of wellbore pressure in such a way that unwanted fluid exchanges between the wellbore and casing annulus are avoided during the circulation of cement slurry and its setting time.

The technique is performed by establishing a closed-loop circulation system; the annulus of the wellbore is accessed by means of a subsea pump through the Low Pressure Housing’s (LPH) flow-by holes. The returns are pumped back to the surface.

Parameters such as return flow rate, pump speed and power consumption by the motors are used to quickly identify any loss or gain. This functionality is crucial for successful placement of cement slurry in extremely narrow drilling windows. By utilising such a system, Enhanced Drilling can offer precise control over the pressure and the flow of the return from the wellbore.

Solution

The MPC® system enables the operator to manage the annular pressure with a subsea pump to compensate for higher/ lower hydrostatic pressure of fluid being displaced in the annulus. As the lighter mud displaces the heavier mud above the planned depth in the annulus, the subsea pump gradually creates back-pressure at the wellhead.

This means that it is possible for the operator to keep the annulus pressure against the critical zone constant. This feature allowed BP to displace 1.70S.G. (14.0ppg) drilling mud to 1.55S.G. (13.0ppg) mud to achieve the desired hierarchy so the 1.75S.G. (14.6ppg) cement could be placed.

A similar scenario occurs when displacing spacers and cement slurry, the difference being that as the denser fluids (spacer and cement slurry) flow above the critical zone, the wellhead pressure is reduced by the subsea pump to keep the pressure at a constant at the point in question. All of this is done in accordance with a perdevised pressure-volume schedule.

Additionally, should any loss of cement slurry to the formation or any flow of fluid from the formation occur, it would be detected by the changes seen in the speed of the pump. The situation can then be easily and swiftly rectified by appropriate adjustments to the pump speed. Having all these features inherent within the system meant that the cement slurry was placed with minimal risk of loss and flow.

Learn more about the MPC® technology here.

Challenge Solved

After the cement was pumped, the annulus was shut in by closing two valves installed on the wellhead. Volumetric reduction of cement slurry as the result of filtrate loss - which would have resulted in significant hydrostatic pressure loss - was prevented. As a result, the annulus was prevented from becoming underbalanced before the slurry developed enough sealing properties. Due to pressure equilibrium reached between the cemented annulus and the formation, formation fluid could not breach the cement. In contrast with the other gas-control techniques applied in the region, BP has not reported any failure of this technique in preventing flow after cementing.

Conclusion

Heavy drilling mud is displaced by a lighter mud in order to achieve desired density hierarchy. Notorious high pressure,unconsolidated water/gas bearing sand strata were successfully isolated with high performance cement in a top-hole section in the Caspian Sea. No water/gas flow after cementing occurred. Well never went underbalanced during cement setting. The operation was done much more safely. Significant cost and time savings due to mitigation of pressure-regime related issues

Want to know more?

Do you have questions regarding this case study or any of our products?

Please don't hesitate to get in touch.

Read Case Study:

RMR® Technology

BP, Egypt

Read Case Study: