EC-Drill®

Managed Pressure Drilling System

MPD system with a Controlled Mud Level (CML) method increasing your operational window

What Is EC-Drill®

EC-Drill® is a Controlled Mud Level (CML) system that enables operators to 'drill the undrillable' well. It solves a long-standing challenge commonly encountered in many deep-water wells: drilling within a narrow pressure window.

With traditional techniques, the slightest excess or lack of wellbore pressure while operating in a narrow pressure window can mean the difference between success or failure: too much pressure and the formation will fracture; not enough will lead to hole instability and increase the chances of influx.

Thanks to the Dual Gradient effect created by EC-Drill, the pressure profiles in the well follows the same trend as the operating window enabling longer sections to be drilled.

Where Do You Apply EC-Drill® Technology

What EC-Drill® Can Do For You

- Enables deep-water drilling to continue uninterrupted for longer periods

- Reduces ECD effect

- Maintains a near-constant BHP

- Improved pressure manipulation enables effective drilling of depleted reservoirs and narrow pressure windows

- May also aid in the drilling of HPHT wells as BHP can be maintained just below fracture pressure

- Flexibility: option to switch to conventional drilling at any time.

How EC-Drill® Works

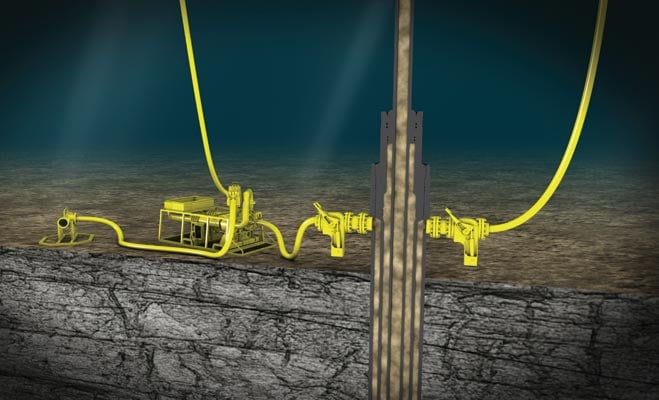

EC-Drill® is a Controlled Mud Level (CML) technology that allows manipulation of bottom hole pressure (BHP) while drilling a well. The system controls the BHP by adjusting the fluid level in the marine drilling riser, and thereby the hydrostatic pressure applied.

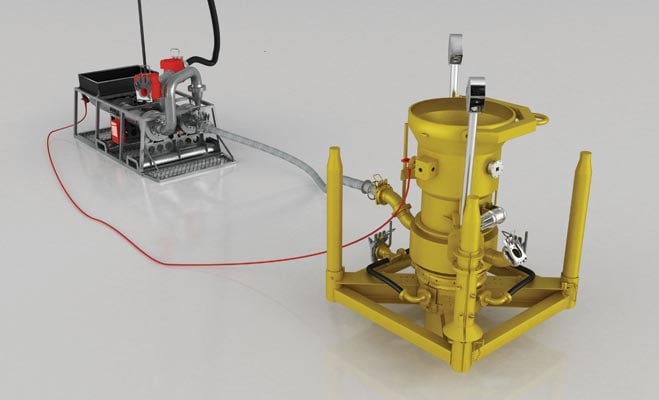

This is achieved by installation of a Subsea Pump Module (SPM) on the riser which pumps all mud and cuttings returns up a separate Mud Return Line (MRL). The system can be used to adjust bottom hole pressure at any point during well construction regardless of whether or not the drill string is currently in the well. It can be used for many applications, including the traditional MPD application of holding BHP constant when pumps are started and stopped during a connection.

By the IADC (International Association of Drilling Contractors) categorization System, EC-Drill® is a Controlled Mud Level (CML) system, it controls the mud level in the marine drilling riser. As a marine drilling riser is installed, the system is only applicable to offshore wells.

EC-Drill®

The EC-Drill® visualisation tool illustrates the Controlled Mud Level (CML) technique that our EC-Drill® MPD technology enables. EC-Drill® controls Bottom Hole Pressure by adjusting the Fluid Level in the riser.

The tool can be used to show:

- Compensation for pumping friction pressure while pumping – increase flowrate and decrease level to stay between pore and frac pressure

- Compensate for cuttings loading – increase the ROP causes cuttings loadings to rise and the associated increase in density of fluid in the well. Use Mud Level to bring this back down between pore and frac

- You can also see how the same BHP can be achieved with a heavier mud weight and reduced riser level which can better fit pore/frac profile in deepwater wells

The tool allows visualisation of the effect on the pressure profile in the well as these parameters are adjusted.

By using the Advanced function, the tool allows you to also select:

- Choice of units

- Adjusting the pore frac profile

- Scaling of the illustration

Frequently Asked Questions about EC-Drill®

FAQ

FAQ

FAQ

FAQ

Do you need RCD with EC-Drill®?

No, EC-Drill® manipulates the fluid level in the marine riser and does not require a Rotary Control Device (RCD) or an additional choke manifold at surface contrary to Surface Back Pressure MPD.

When can EC-Drill® be used?

EC-Drill® use is limited to offshore wells. It is normally used on wells drilled from floating rigs (semi-submersible or drillship) using a subsea BOP. EC-Drill® has also been used on jack up rigs during the initial hole sections taking suction from the conductor. There is also application for use on specific platform applications with a surface BOP when a subsea casing hanger system and separate drilling riser is used.

Where has EC-Drill® been used?

EC-Drill® to date has been used offshore Brazil, offshore Mediterranean, in the North Sea, in the Barents Sea and in the Gulf of Mexico. It is applicable from shallow to ultra deep water application, with jack-up, semi-submersible or drillship.

Can I perform cementing operations with EC-Drill®?

Yes, EC-Drill® is well suited to manage pressure during cementing operations. The EC-Drill® system can easily perform Managed Pressure Cementing (MPC) in an operationally convenient manner. The combination can allow for use of more conventional cementing techniques in some cases.

Do you need a MPD ready rig?

EC-Drill® does not require a MPD ready rig as it can install on any offshore mobile drilling unit. The surface pipework that is required by EC-Drill® is minimal. If the rig is “MPD ready” for Surface Back Pressure (SBP) MPD, some of this pipe work can likely be used, but the amount EC-Drill® surface pipework is small, and this would not be a major factor in installation of EC-Drill® on a rig.

What is an EC-Drill® ready rig?

An EC-Drill® ready rig is in a rig where the supporting equipment is available to allow operation to commence within a short lead time. The only equipment to be mobilized is a Subsea Pump Module and Control system.

Do I need to change EC-Drill® between sections?

How fast can EC-Drill® be mobilized?

With the popularity of EC-Drill®, the equipment is subject to availability. With available EC-Drill® equipment, the limiting factor will be rig integration time. The 3rd party modified riser joint is typically a longest lead item, with a usual lead time of 6 months, although 3 months lead time has been achieved on previous projects.

Case Studies

EC-Drill® Dual Gradient

Learn how EC-Drill® reduced casing points in Deepwater Drilling. A common challenge for Deepwater wells is the need for multiple sections.

EC-Drill® benefits displayed on Shah Deniz

Learn how BP drilled a top-hole section on the Caspian’s Shah Deniz field through hazardous formations in terms of shallow water/gas flow from a fixed platform usin EC-Drill technology®

EC-Drill® - Instant kick detection in GoM

Learn how a multi-national operator recently used EC-Drill®’s instant kick detection service to complement and enhance conventional kick detection methods during deep-water exploratory drilling in the Gulf of Mexico.

Watch How The EC-Drill® Technology Works

Brochures

Get in depth knowledge about the EC-Drill system by reading our product material